Fasteners

Like Your Business

Depends on it...

The Right Part, for the Right Application, Right when you need it.

Right when you need it.

- Exceptional Customer Service

Not sure what you need? Speak to a UC engineer or experienced cleanroom production expert. - 100% Parts Traceability

OEM-level documentation tracks every product in detail, from mining to print to installation. - RediVac® = Clean-tech Standard

All UC products arrive pre-cleaned, vacuum sealed, rigorously inspected and ready to install.

View Standard Products

Can’t Find What You Need?

Call for Custom Solutions & Prototypes

We Take Service to the Extreme

- When you call UC, you get a live engineer, not an order taker or machine.

- Not sure what you need? A UC expert will help you find the perfect part and finish.

- From student to scientist, no UC customer is ever too small -and no job too big.

- We say what we do, and do what we say, RediVac® counted, cleaned, consistent.

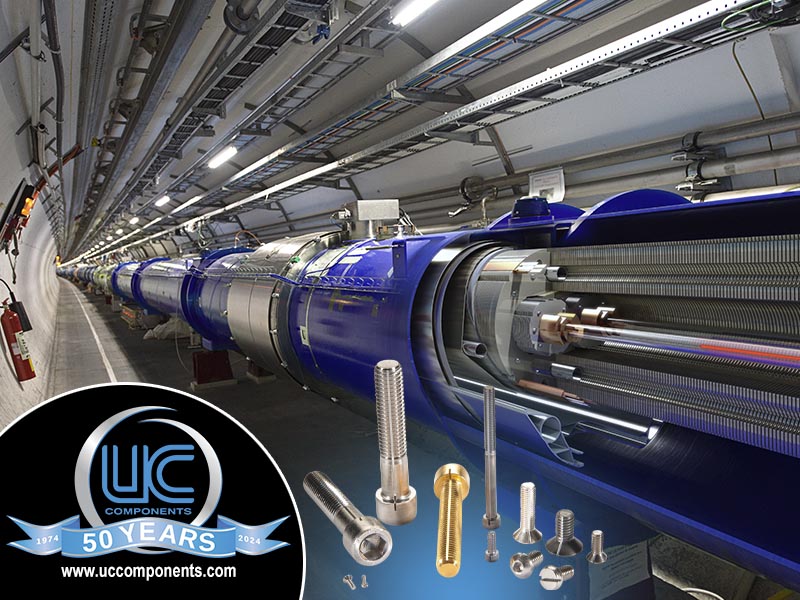

Our online parts catalog contains tens of thousands of SKUs, however over half of what we manufacture isn’t listed. We specialize in custom orders and prototypes focused on plated, coated, polished, cleaned, and vented fasteners for High and Ultra-High Vacuum applications.

Resources & Content

Supporting and Enhancing Food Processing Equipment with Vented Fasteners

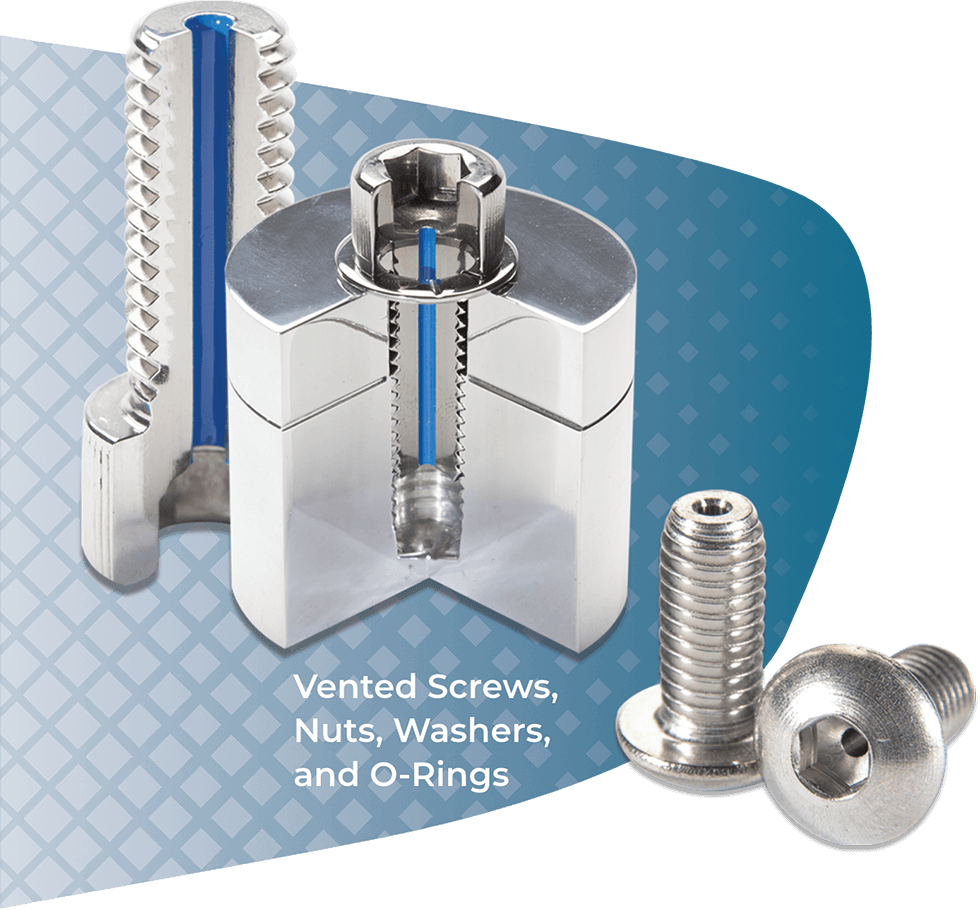

Vented fasteners play a crucial role in food processing equipment by enhancing efficiency, sanitation, and operational reliability. These specialized fasteners, including bolts, screws, hex nuts,

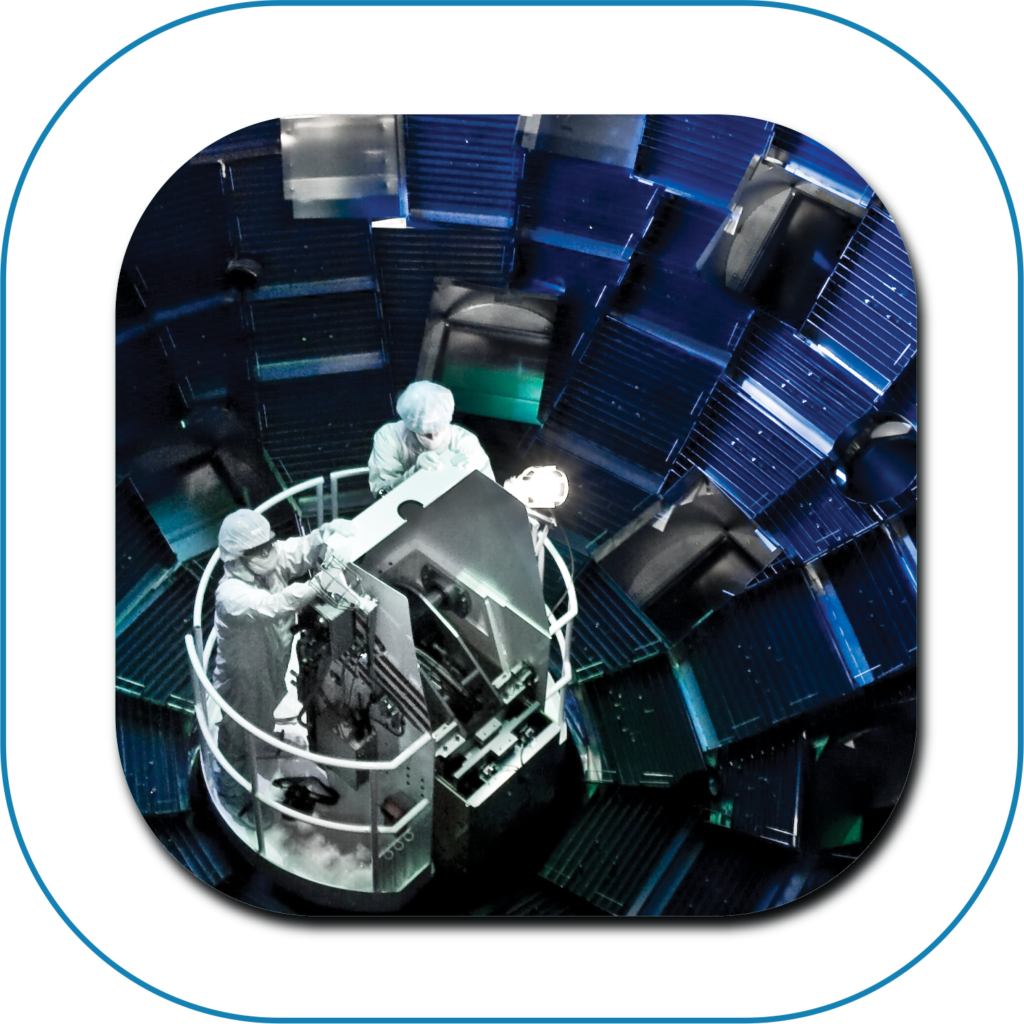

How do vented fasteners support beamline applications?

Vented fasteners are critical components in beamline applications, where maintaining an ultra-high vacuum and ensuring the structural integrity of complex assemblies are paramount. These specialized

Kolsterising®: The Ultimate Surface Hardening Solution for Durable and Corrosion-Resistant Fasteners

Kolsterising®, a revolutionary fastener treatment, is redefining standards for clean-critical applications across various industries. The process involves diffusing carbon into the material’s surface without forming

Fastener Laser Head Marking: A Seamless Extension of our RediVac® Process

UC Components’ laser head marking service is designed to integrate seamlessly with our proprietary RediVac® process, delivering an even greater level of control, traceability, and

UPCOMING TRADESHOWS

Connect with us at a tradeshow! Send a message now to schedule a meeting with our team.

February 11-13

COEX, Seoul, Korea

Booth #W805

February 26

Fremont, California