and Seal Solutions

What's At Stake? Everything.

UC Components, Inc. RediVac® products are used in the manufacture of semiconductors, wafers, and microelectronics… at every level of production.

Semiconductor manufacturing, which typically utilizes ultra high vacuum (UHV), is among the most demanding industrial environments from the standpoint of outgassing and particulate contamination. A particle as small as one micron in size can cause a short in a device costing tens of thousands of dollars to produce. A single fingerprint can have the same damaging effects in the form of outgassing.

Can you afford a poor fastener choice?

Critical Applications

Wafer and Substrate materials defects reduced with Quality components.

CVD, PVD and ALD Equipment require routine replacement of fasteners.

Circuit and Device Pattering, Steppers & Aligners need special material selections.

Address Metrology Analyzation and Characterization tool sensitivity to contamination.

The right part, for the right application, right when you need it.

Part Traceability

From print to installation, every part is fully traceable, down to the last screw.

Quality Control

UC’s obsessive attention to detail comes from a fierce commitment to your success.

Application Expertise

Our Certified Fastener Specialists™ are experts in your industry, and available to solve your problem now.

Don’t know what you need?

Our specialists do, and will guide you.

1. Call a UC Engineer

2. We Review & Spec

3. Problem. Solved.

No matter what the requirements of your semiconductor application, we have the vacuum-ready components you need: from silver plated screws to vented washers to vacuum-baked O-rings and more.

Resources & Content

Are in-person or virtual meetings with our fastener specialists possible?

When you call us you will get a live person...

Read MoreUC Components, Inc. is proud to announce sponsorship of the 13th Annual Operation Freedom Paws Charity Golf Tournament

UC Components, Inc. announces a corporate “UC CARES” sponsorship of...

Read MoreHave you tried our live website chat feature?

When you call us you will get a live person…...

Read MoreNavigating the Skies: A flawed fastener can make or break your mission

A recent article about NASA opening a canister containing material...

Read More

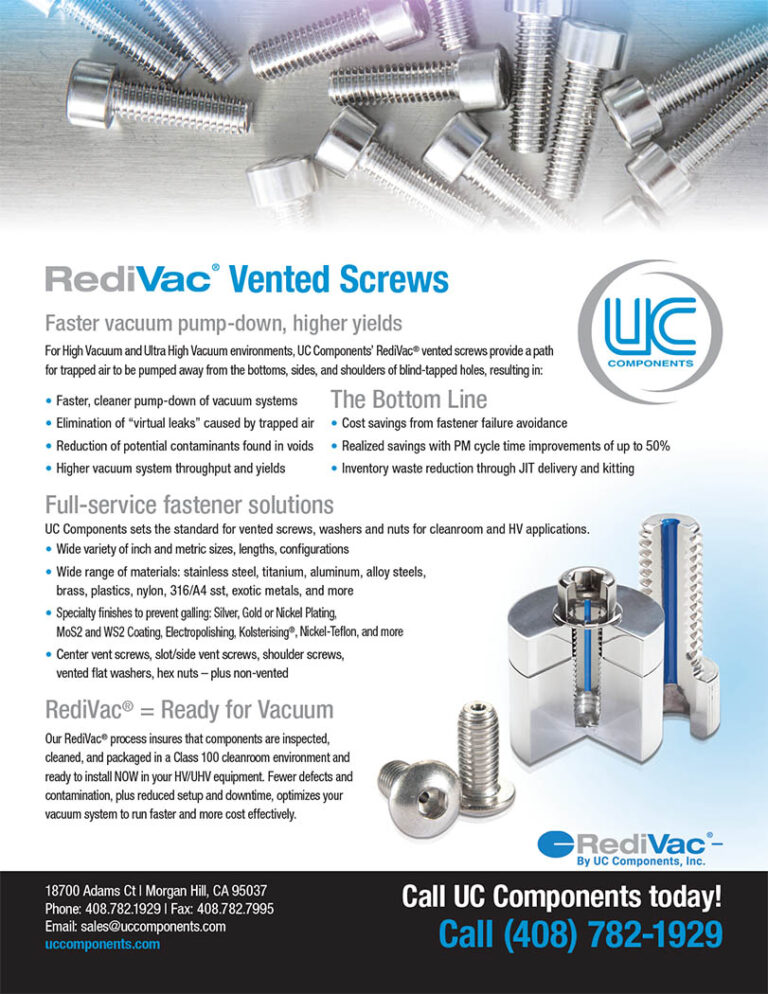

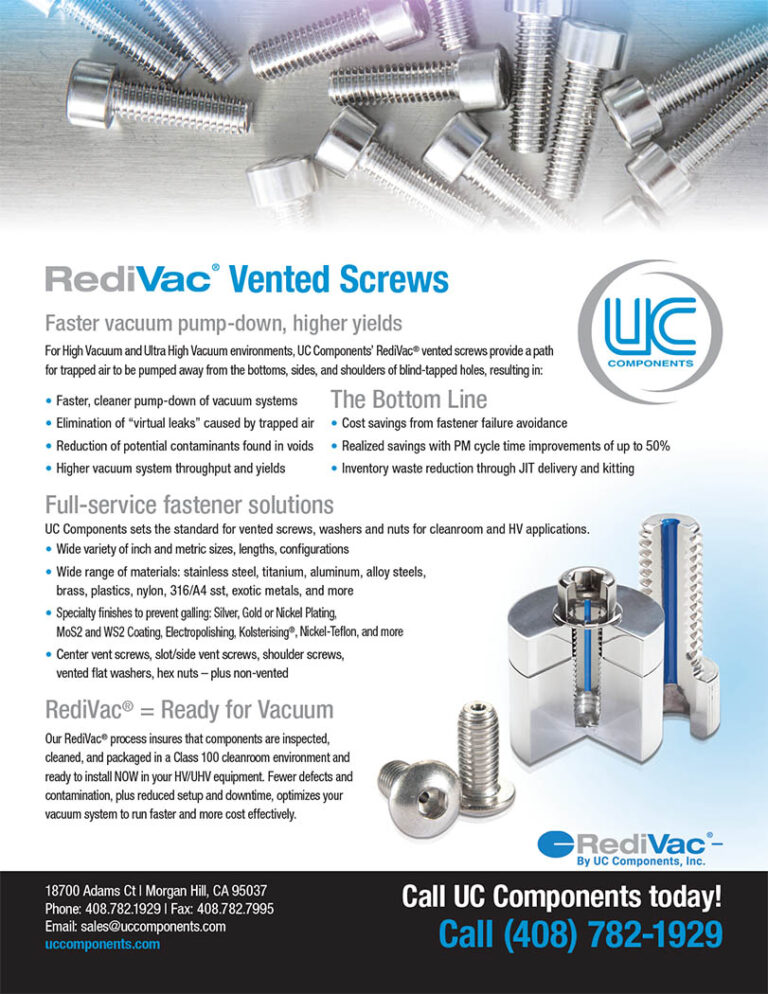

What is a Vented Screw and Why Would You Need One?

Vented Screws are also known as Vacuum Screws, Ventilation Screws, or Hollow Screws. A vented screw features a hollow core (has a hole drilled through it) and are specially designed to allow the release of gases, contaminants, and pressure through the fastener. Vented Screws are widely used within vacuum systems and enable faster, more efficient pump-down of HV, UHV, and EUV systems.

Simply Galling and the Fasteners it Ruins

Galling is one the most common problems when tightening fasteners. Galled nuts and bolts may even pass all required inspections (mechanical, threads, material, etc.), yet they can still fail to function properly. Galling tends to be more common in alloys that self-generate an oxide surface film for corrosion protection like stainless steel, aluminum, and titanium.

Screw Series - Part 1: What are Shoulder Screws?

There are wide varieties of fastener hardware on the market today used by manufacturers in the assembly of every single product we use daily. Shoulder screws, while not typically found in your local hardware store, are extensively used in almost every industry because they are incredibly versatile and offer unique attributes when installed.