Kolsterising® (-KOL/-N-KOL)

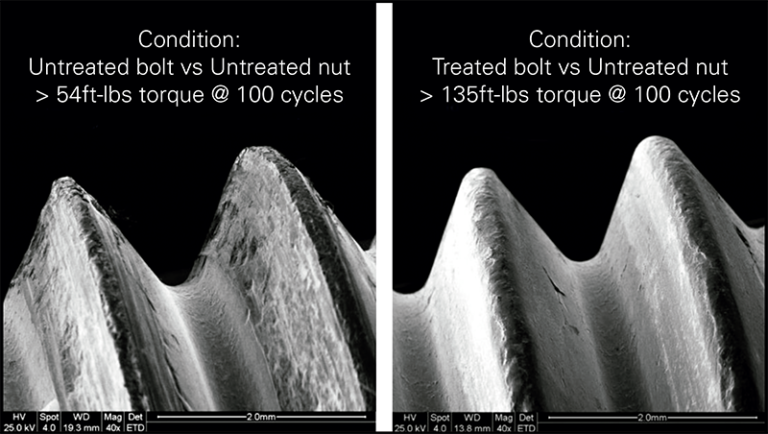

Kolsterising® is an industry-proven, thermo-chemical, low-temperature, diffusion-based, surface hardening technology used to enhance certain grades of stainless steel, cobalt, and nickel-based alloys. Kolsterising® is not a coating but a low-temperature surface carbon diffusion treatment that enhances the hardness of the base material. The process adds large concentrations of carbon atoms that form high compressive stresses on the surface. These stresses and the filling of the interstitial sites by the carbon atoms not only significantly improves the hardness of the material, but also makes the surface resistant to corrosion, wear, and fatigue.

Kolsterising® is ideal for applications such as:

- Medical devices that require biocompatible materials

- Pharmaceuticals

- Fasteners

- Valve parts (balls, needles, seats, and housings)

- Food and beverage filling/dispensing machine pistons and seals

- Automotive components

- Marine parts

- Industrial fluid handling

- And so many more

Kolsterising® eliminates:

- Delamination

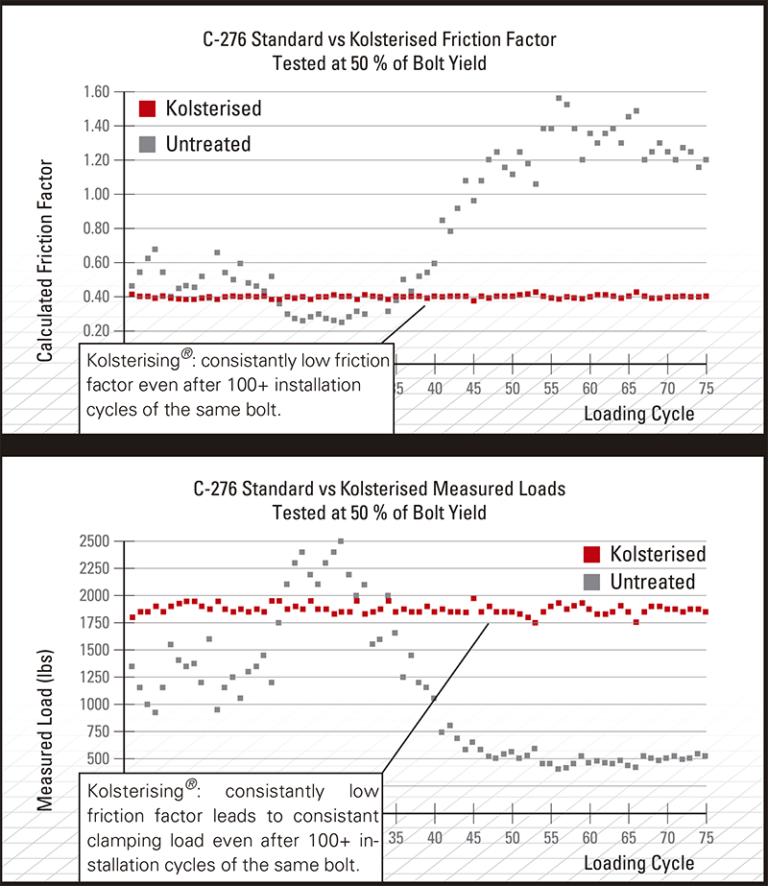

- Galling in stainless steel alloys

- Metal debris

Why chose Kolsterising®?

- Complex shapes can be effectively hardened by this process

- It offers consistent diffusion depth

- Improved abrasive wear

- Improved cavitation erosion resistance

- Increased fatigue strength

- Reduces galling

- Exceptional scratch resistance

- Does not affect the magnetic properties of the metal alloys

- Good dimensional stability

- The process does not change the part dimensions

Kolsterising® allows designers and engineers to use more common and inexpensive materials, while giving them the performance expensive alloys. The treatment can improve some austenitic and martensitic grades of metal, ferritic and duplex stainless steel, as well as certain cobalt-chromium and nickel-based alloys.

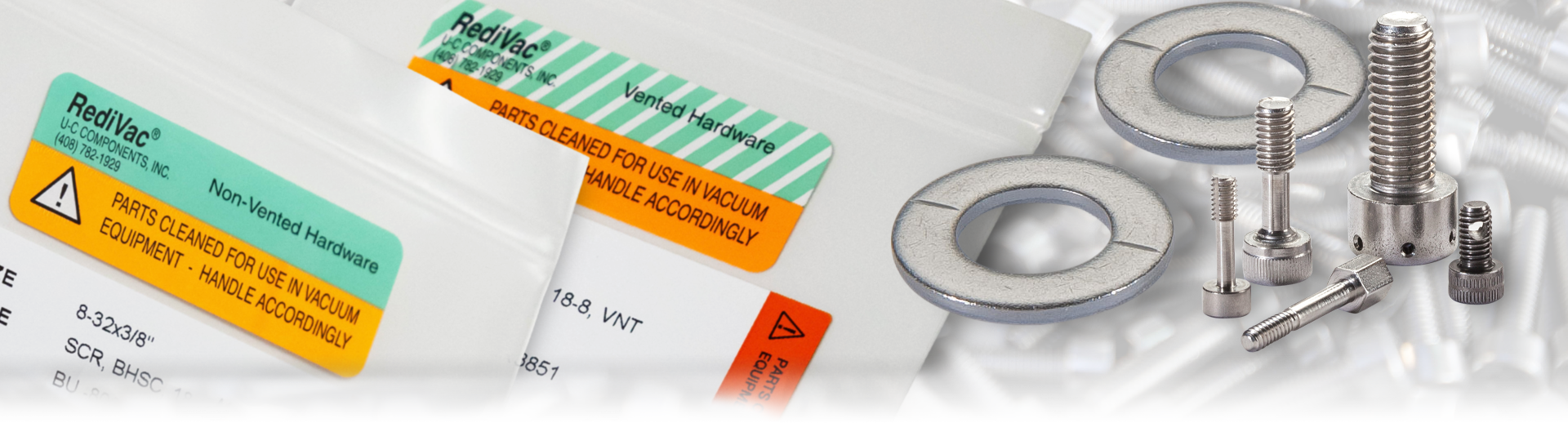

While the right coating or plating for your HV or UHV application is best defined by your process engineer, we are always here to assist you. UC Components, Inc. has been the world leader in high vacuum hardware since 1974.

UC Components, Inc.’s RediVac® fasteners, washers, nuts, and O-rings are designed for use in a wide range of high vacuum applications and other clean-critical environments. We offer a variety of specialized venting designs, numerous finishes, and complete Class 100/ISO Class 5 Cleanroom cleaning and packaging.