and Seal Solutions

What's At Stake? Everything.

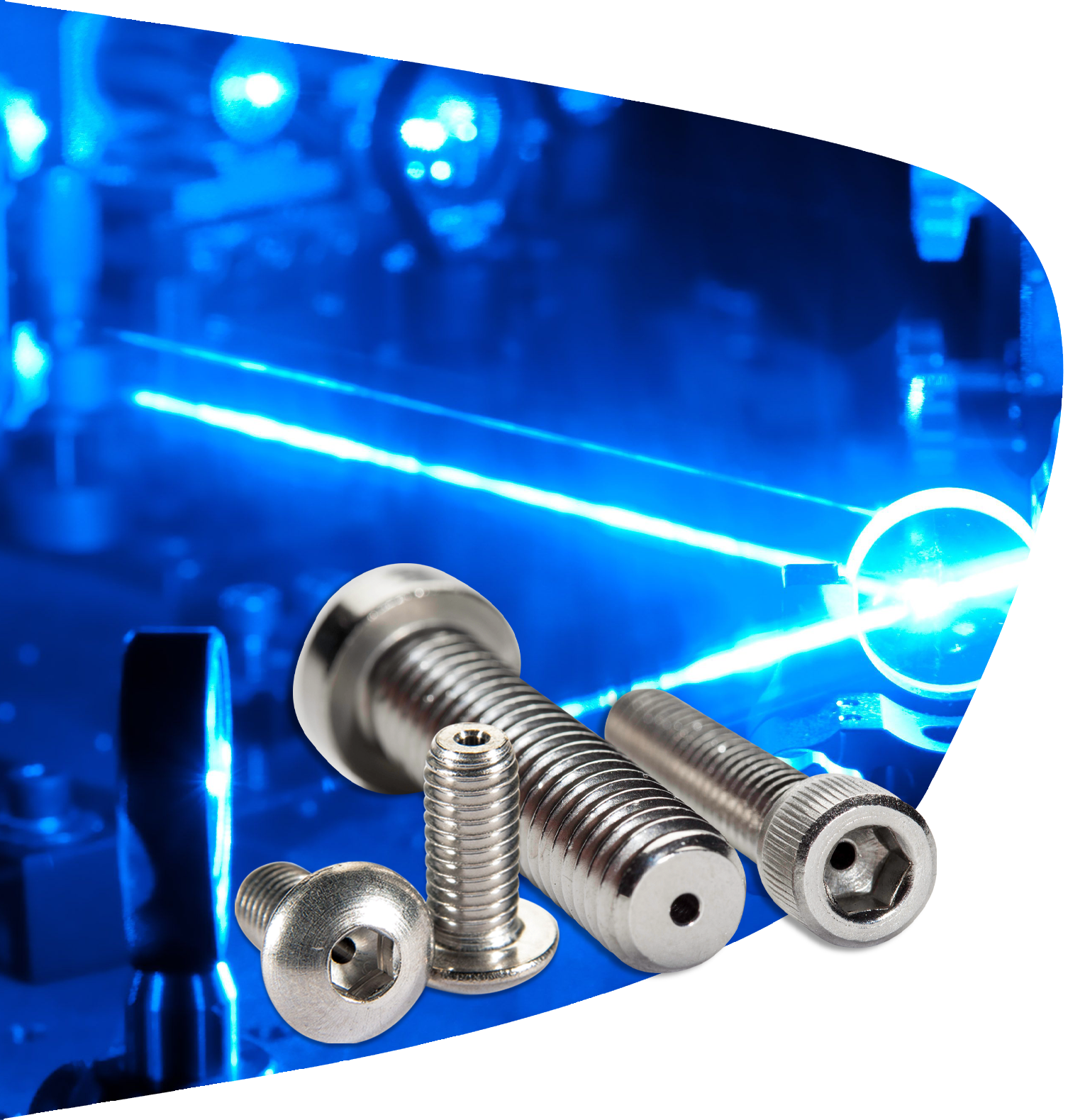

Fiber optics, lens coating, laser optics, and IR detectors are just a few of the optical devices currently manufactured under vacuum, and the list is growing.

Many of these processes will see the greatest benefit from improved contamination control, particularly in the reduction of outgassing from O-rings, a primary source of optical surface contamination.

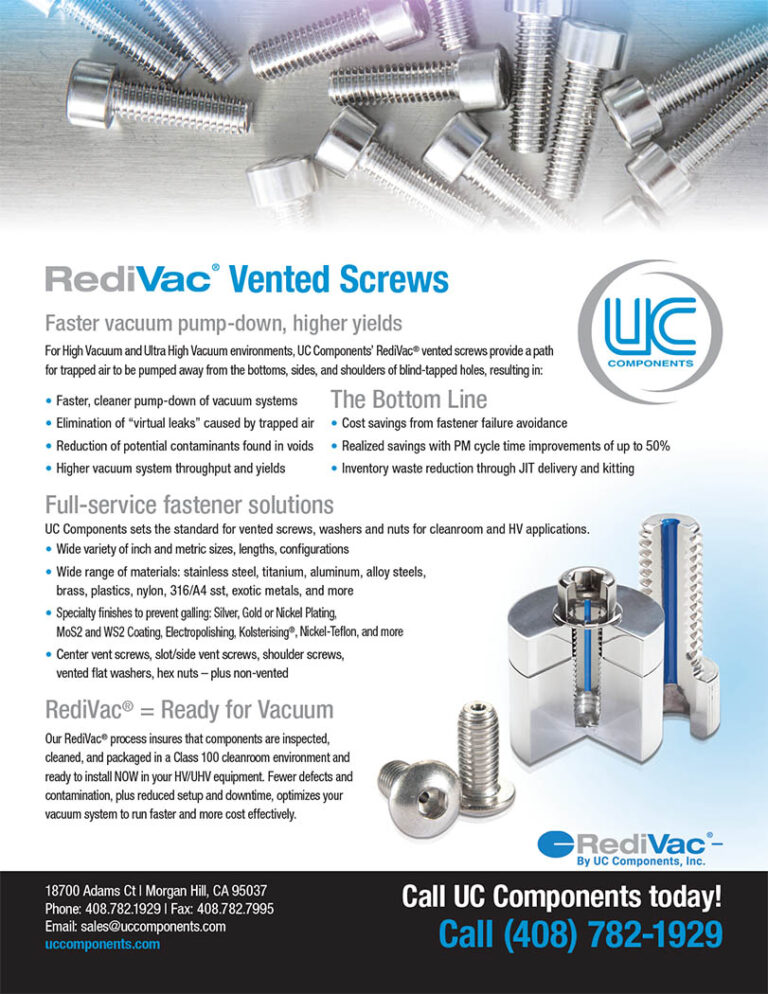

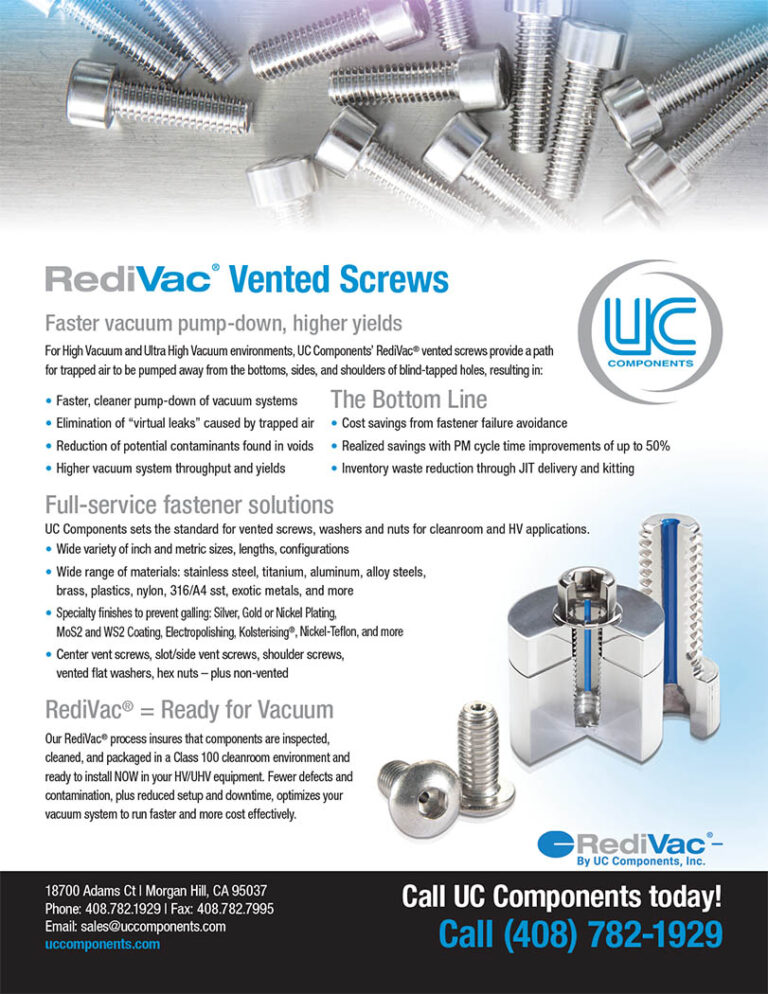

UC Components, Inc. RediVac® fasteners and seals help optics manufacturing chambers achieve more efficient, higher yield, production.

We deliver solutions – vented, plated, polished, inspected, and clean room-ready – exactly as promised.

Guaranteed.

Critical Applications

Lens Manufacturing and Coating Equipment replacement fasteners.

Prevent Mounting fixtures, Beam alignment structures from Galling.

Keep Internal and External light generated emission units free of particulates.

Optoelectronic components construction needing fastener assurance.

The right part, for the right application, right when you need it.

Part Traceability

From print to installation, every part is fully traceable, down to the last screw.

Quality Control

UC’s obsessive attention to detail comes from a fierce commitment to your success.

Application Expertise

Our Certified Fastener Specialists™ are experts in your industry, and available to solve your problem now.

Don’t know what you need?

Our specialists do, and will guide you.

1. Call a UC Engineer

2. We Review & Spec

3. Problem. Solved.

Resources & Content

Are in-person or virtual meetings with our fastener specialists possible?

When you call us you will get a live person...

Read MoreUC Components, Inc. is proud to announce sponsorship of the 13th Annual Operation Freedom Paws Charity Golf Tournament

UC Components, Inc. announces a corporate “UC CARES” sponsorship of...

Read MoreHave you tried our live website chat feature?

When you call us you will get a live person…...

Read MoreNavigating the Skies: A flawed fastener can make or break your mission

A recent article about NASA opening a canister containing material...

Read More