Fasteners

Like Your Business

Depends on it...

The Right Part, for the Right Application, Right when you need it.

Right when you need it.

- Exceptional Customer Service

Not sure what you need? Speak to a UC engineer or experienced cleanroom production expert. - 100% Parts Traceability

OEM-level documentation tracks every product in detail, from mining to print to installation. - RediVac® = Clean-tech Standard

All UC products arrive pre-cleaned, vacuum sealed, rigorously inspected and ready to install.

View Standard Products

Can’t Find What You Need?

Call for Custom Solutions & Prototypes

We Take Service to the Extreme

- When you call UC, you get a live engineer, not an order taker or machine.

- Not sure what you need? A UC expert will help you find the perfect part and finish.

- From student to scientist, no UC customer is ever too small -and no job too big.

- We say what we do, and do what we say, RediVac® counted, cleaned, consistent.

Our online parts catalog contains tens of thousands of SKUs, however over half of what we manufacture isn’t listed. We specialize in custom orders and prototypes focused on plated, coated, polished, cleaned, and vented fasteners for High and Ultra-High Vacuum applications.

Resources & Content

The State of Fasteners in 2026: Precision Is Not Optional

As manufacturing environments continue to evolve in 2026, so has the role of the fastener. Once viewed as a commodity, fasteners are now increasingly recognized

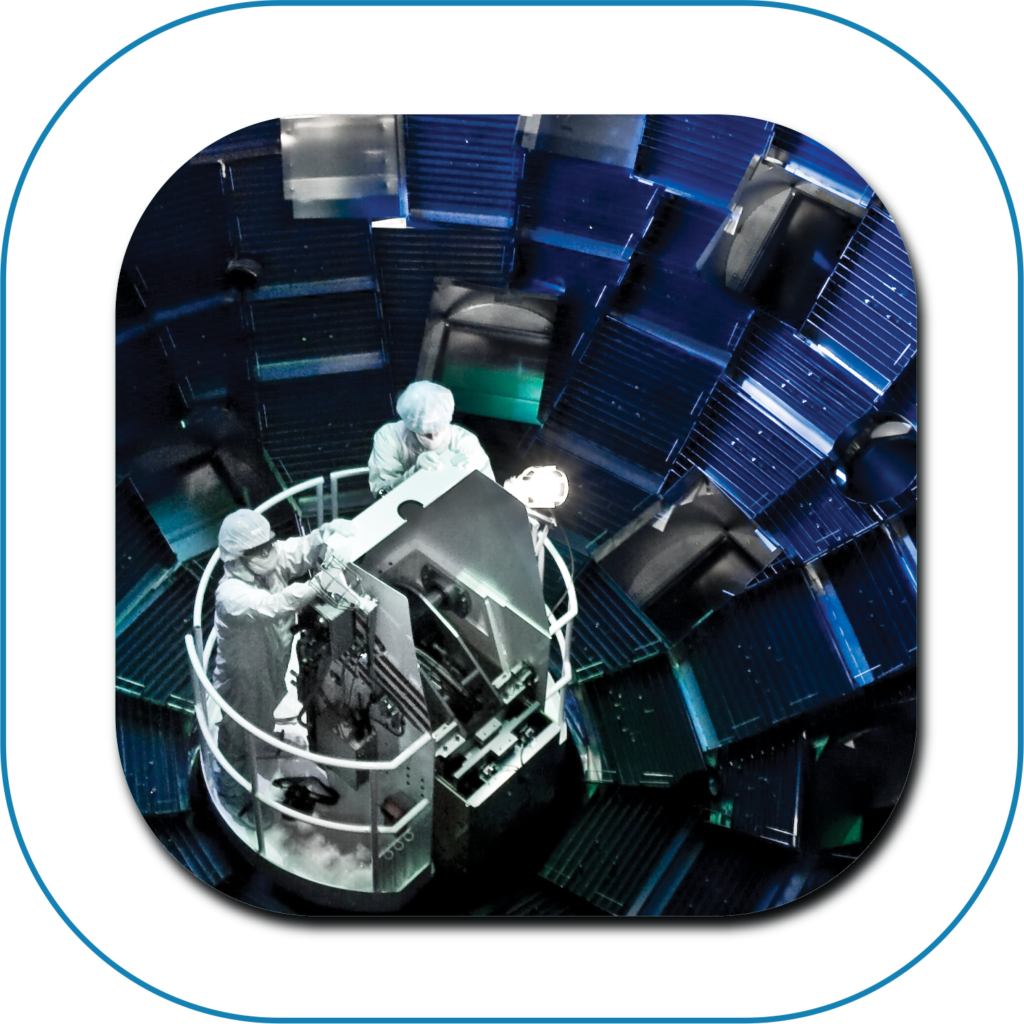

Utilization of 12-Point Bolts in Beamline Applications

12-point bolts, or twelve-point flange bolts, are high-performance fasteners designed to handle high-stress environments. They are characterized by a bolt head with 12 points of

Supporting and Enhancing Food Processing Equipment with Vented Fasteners

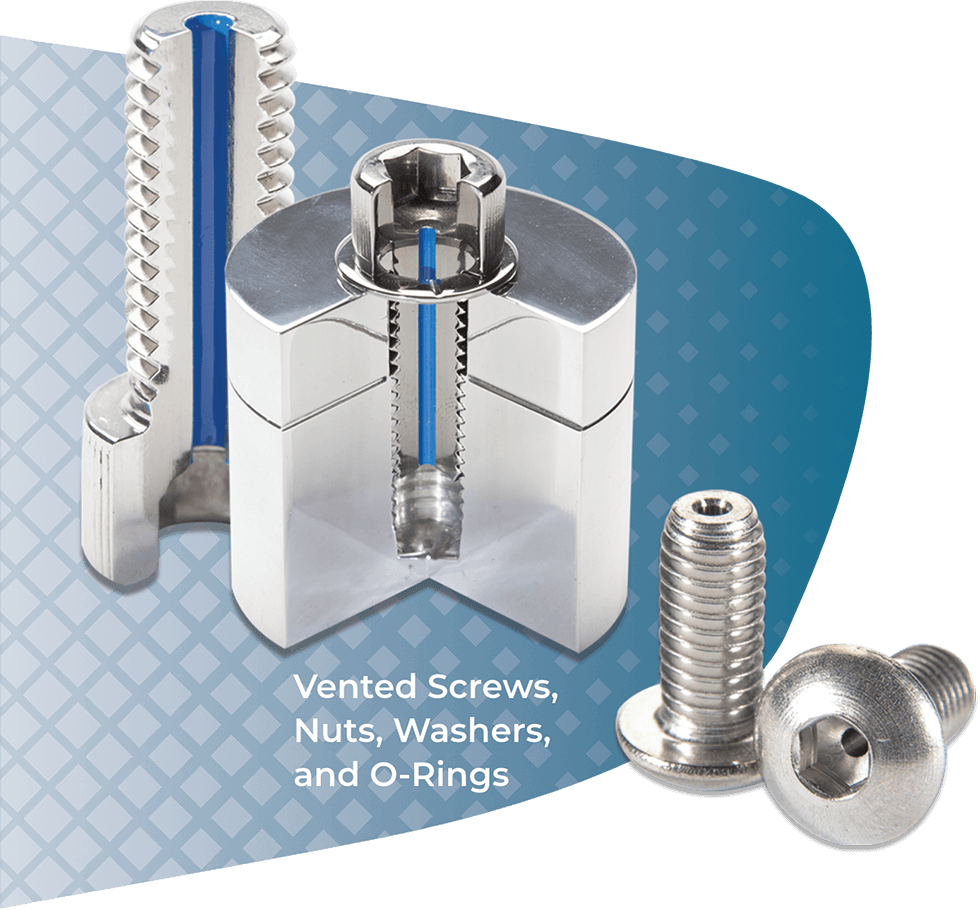

Vented fasteners play a crucial role in food processing equipment by enhancing efficiency, sanitation, and operational reliability. These specialized fasteners, including bolts, screws, hex nuts,

Conferences of Interest

Please find below upcoming industry conferences and trade shows that may be of interest to you. Visit the Northern California AVC Chapter website Visit the

UPCOMING TRADESHOWS

Connect with us at a tradeshow! Send a message now to schedule a meeting with our team.

Honolulu, HI

Long Beach, CA