Vented fasteners are critical components in beamline applications, where maintaining an ultra-high vacuum and ensuring the structural integrity of complex assemblies are paramount. These specialized fasteners, distinguished by a small vent hole through their body, are designed to quickly eliminate trapped air and gases that could otherwise compromise the vacuum environment.

What is a beamline?

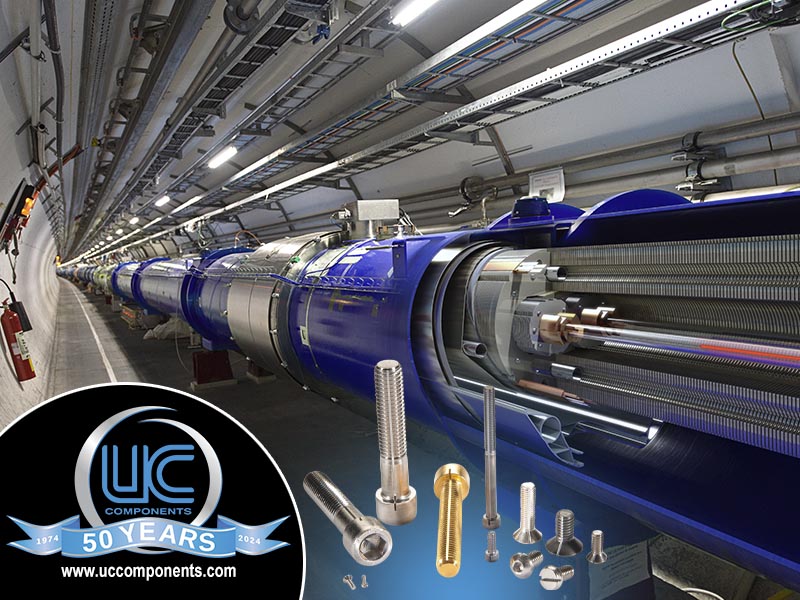

Beamlines refer to the systems and processes used in particle accelerators and synchrotron facilities, where beams of particles or light are directed along a specific path, or “beamline,” for scientific research. These applications are crucial for experiments in fields such as materials science, biology, chemistry, and physics. Beamlines are designed to manipulate, focus, and direct beams of particles or radiation, often under ultra-high vacuum conditions, to target samples or detectors. Researchers use these applications to study the properties of materials at atomic or molecular scales, conduct crystallography, investigate chemical reactions, and perform other precision experiments. The high precision and controlled environment provided by beamline systems are essential for producing accurate, reproducible results in advanced scientific research.

What part do vented fasteners play in beamline applications?

In beamlines, where precision and reliability are essential for conducting advanced scientific research, vented fasteners are crucial in reducing outgassing, speeding up the vacuum pump-down process, and enhancing overall system stability. Their use ensures that beamline systems operate at peak efficiency, supporting accurate and reproducible experimental results.

How exactly do they help? The use of vented fasteners in beamline applications offers several benefits, including:

1. Efficient Pump-Down

- Rapid Vacuum Achievement: The fastener’s vent enables faster air evacuation from blind holes and cavities, which helps achieve the desired vacuum level more quickly. This is particularly important in beamline applications where precise vacuum conditions are needed.

2. Thermal Considerations

- Heat Distribution: In some cases, vented fasteners can also assist in evenly distributing heat during the bake-out process, ensuring that all components reach the desired temperature uniformly, which is critical for vacuum integrity.

3. Structural Stability

- Preventing Pressure Differences: Vented fasteners help equalize pressure across different parts of the assembly. This prevents deformation or mechanical stress that might arise due to trapped air or gases expanding during temperature changes, thereby maintaining the structural stability of the beamline components.

4. Improved Assembly and Maintenance

- Ease of Assembly: Vented fasteners make it easier to assemble and disassemble components in a vacuum system without worrying about trapped air or gases that could lead to difficulty maintaining the vacuum.

- Enhanced Reliability: By ensuring that there are no hidden pockets of air or gas that could cause issues during operation, vented fasteners enhance the overall reliability of beamline systems.

Vented fasteners enhance the reliability and performance of beamline systems, making them a critical component in these advanced scientific applications.

Why choose fasteners from UC Components for beamlines and other critical applications?

UC’s fasteners have been instrumental for vacuum and other clean-critical applications since 1974. We proudly support and supply the fasteners for many educational and scientific research applications and facilities, including Argon National Lab, Cern, Lawrence Berkely Lab, Lawrence Livermore National Lab, Sandia National Laboratories, Stanford Linear Accelerator Center, and more.

We offer a wide variety of fasteners and O-rings, including, but not limited to, standard and vented screws, washers, and hex nuts in multiple materials. We offer numerous finish options, specialized venting designs, complete custom product development, and Class 100/ISO Class 5 Cleanroom cleaning & packaging.

View our parts catalog online to find the components you need, request a quote, or contact us for more assistance or additional information. If you do not see the fastener, material, or O-ring that you need listed in our standard products, please give us a call! We may not stock it, but we are happy to acquire or manufacture just about any fastener or O-ring you need. A live Certified Fastener Specialist is waiting to hear from you and will help you find the perfect part and finish. From student to scientist, no UC customer is ever too small – and no job is too big!