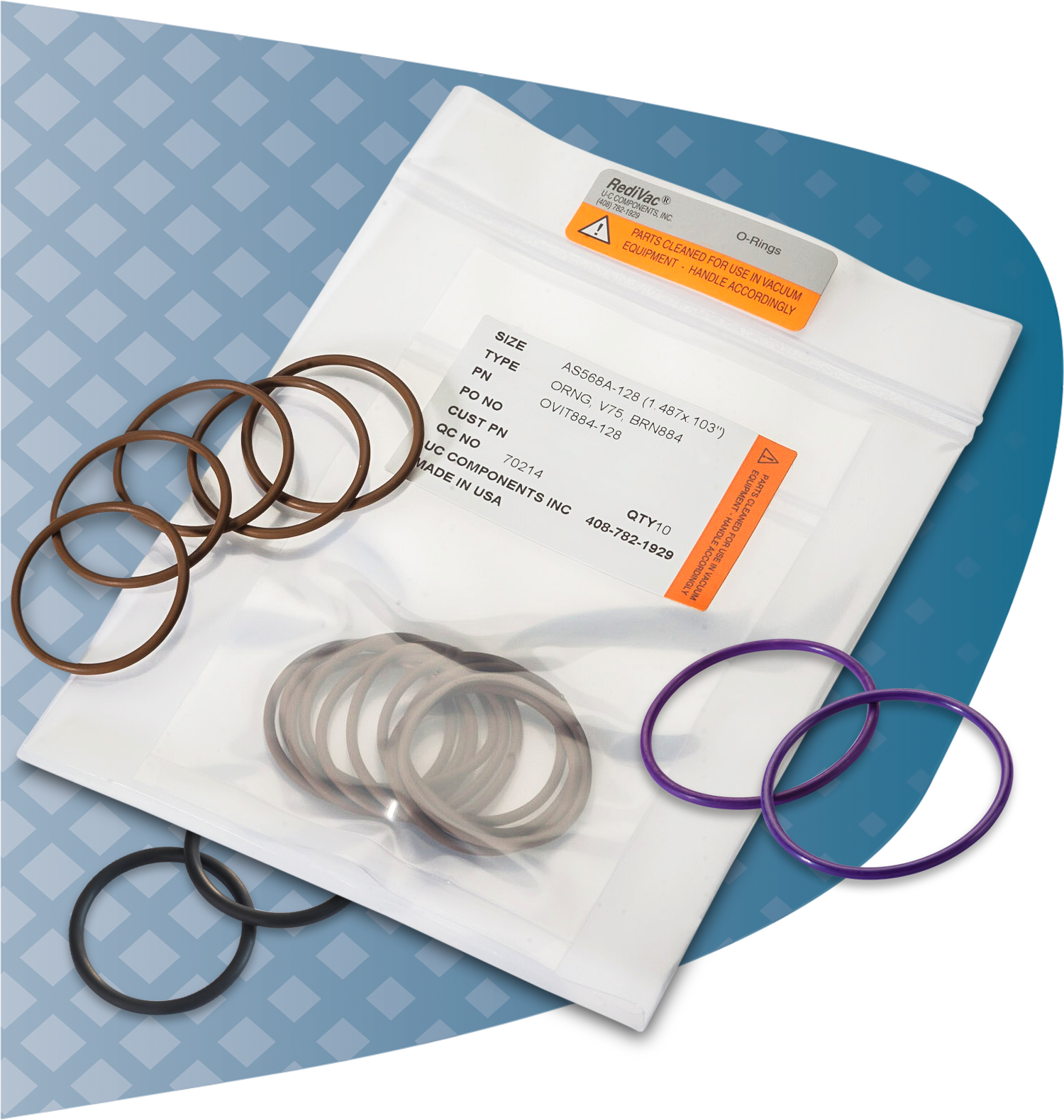

SUPERB QUALITY O-RINGS FOR HIGH & ULTRA-HIGH VACUUM APPLICATIONS

Experts in vacuum technology bring you RediVac® O-Rings for your high and ultra high vacuum applications, designed specifically to enhance your system performance and integrity.

REDIVAC® O-RINGS FOR HV, UHV, & EUV APPLICATIONS

UC Components, Inc. is known worldwide for providing fastener and seal solutions dedicated to improving the performance and integrity of vacuum systems and other clean-critical environments.

REDIVAC® MEANS READY FOR VACUUM SERVICE, NOW!

Directly from our cleanroom to yours, our RediVac® system guarantees that your fasteners and seals arrive ready to install in your HV, UHV, or EUV system immediately.

Our proprietary RediVac® process reduces surface particulates and other contamination by utilizing:

-

a multi-stage precision cleaning process,

-

close inspection of each O-ring,

-

and state-of-the-art vacuum packaging equipment

… all done within a certified Class ISO Class 5 Cleanroom.

By reducing additional vacuum preparation steps, UC Components’ RediVac® products help you run faster and leaner.

WHAT MAKES REDIVAC® O-RING TECHNOLOGY SO EFFECTIVE?

UC Components knows vacuum systems.

As the industry leader we provide the right solutions, following stringent quality standards, for your applications.

-

The UC RediVac® O-Ring product line is engineered for faster pump-down and more complete evacuation of vacuum systems.

-

RediVac® seals are cleaned and baked to minimize outgassing under vacuum.

-

All of our products are designed for High Vacuum (HV) and Ultra High Vacuum (UHV) applications.

The RediVac® line of cleaned and vacuum-baked fluoroelastomer (FKM) O-Rings is designed to deliver a ready-to-use seal to the point of use with a thorough surface cleaning and/or vacuum de-gassing for quicker pump-down and reduced contamination.

UC Components’ RediVac® O-Rings are available in a wide range of inch-measure sizes that are manufactured to industry standard AS568A sizes.

Every one of our RediVac® O-Rings goes through our multi-stage precision cleaning and packaging processes prior to shipment, ensuring that the components you receive are ready for immediate installation into your HV, UHV, or clean-critical system.

Our precision cleaning process significantly reduces surface particulate and other organic surface contaminants, utilizing a variety of cleaning methods and state-of-the-art vacuum packaging equipment.

REDIVAC® VACUUM BAKED O-RINGS

Our RediVac® Vacuum Baked O-Rings offer an added level of cleanliness assurance by minimizing residual hydrocarbons and water vapor.

Our Vacuum Baked O-Rings:

-

Significantly reduces outgassing and residual surface contaminants

-

Reduces water vapor and limited volatile organics

-

Does not significantly alter the O-Ring hardness

Contact your UC Components, Inc. sales representative for custom materials, baking recipes, and packaging options.

The benefits – and product quality – of our RediVac® O-Rings make them the product of choice for numerous high and ultra-high vacuum systems. Our O-Rings deliver high performance and stability for vacuum systems of all levels of sensitivity; they also feature strict quality measures in sourcing, cleaning, handling, and packaging.

Our RediVac® O-Rings Feature:

-

Custom Materials Available: Our standard O-Rings are manufactured from top quality fluoroelastomer materials. Buna, silicone, and other materials are available upon request.

-

Wide Variety of Sizes to Meet Any Need: All of our O-Rings are available in just about any size you need for your application.

-

Two Finishing Options to Choose From: Precision Cleaned and Vacuum Baked. Ensuring that the components you receive are ready for immediate installation into your HV or UHV system which greatly reduces outgassing and residual surface contaminants.

-

No More Vacuum Leaks: Significantly reduces outgassing as well as minimizing residual surface contaminants, hydrocarbons, and water vapor.

-

Optimum System Integrity and Stability: Our O-Rings meet or exceed the requirements of many of today's leading scientific research facilities, beam lines, and test chambers operating HV and UHV environments.

Request a quote for RediVac® O-Rings for high and ultra-high vacuum applications,

or contact UC Components for more information.