Determining the exact size of an O-ring is one of the more challenging parts of ordering O-rings for your application. As you know, O-rings are used to create an impenetrable seal. If the O-ring is too large, fluids, gasses, dirt, water vapor outgassing under vacuum, and more will flow around it. If the O-ring is too small, overstretching it to fit it into place will compromise the O-ring’s integrity and can cause it to fail. Knowing how to properly size an O-ring is important to avoid O-ring failure and avoid wasting time and money. Sizing an O-ring isn’t tricky, but it is crucial that you are precise.

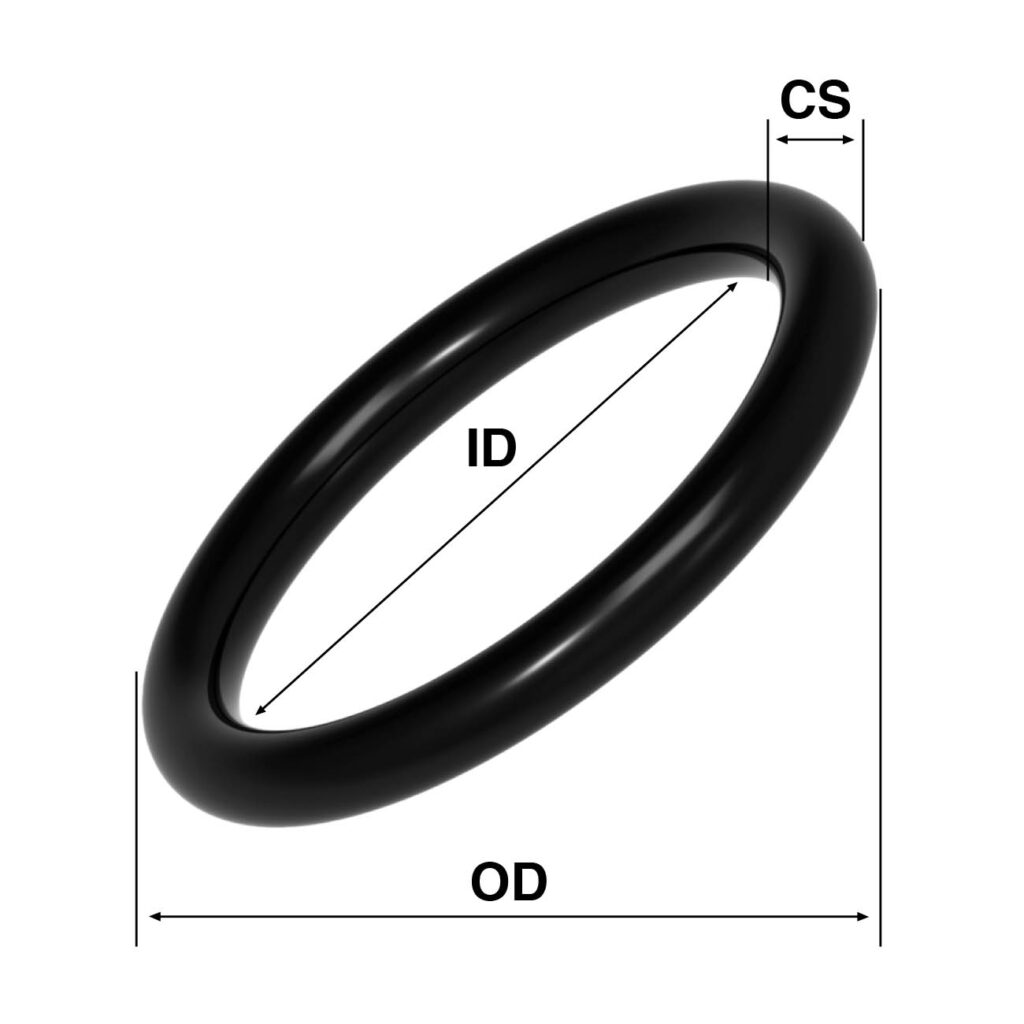

The best way to size an O-ring is to measure the cross-section (CS) as well as the inside diameter (ID) of the O-ring with a caliper or micrometer. The outside diameter (OD) is good to note but is a non-critical measurement. If you do not have these tools, you can use any measuring tool that you have available; a caliper or micrometer will be more accurate. For larger IDs over 6”, it is best to use an O-sizer or Pi-Tape for precise measurements.

Metric VS Standard Sizes

All O-rings either come in metric (mm) or standard (inch) sizes. If your CS matches one of the standard AS586 sizes (such as 0.70”, 0.103”, 0.210”, etc.) then your O-ring is most likely a standard size. If it does not match, then the odds are good that you have a metric O-ring.

Here is how to properly measure an O-ring:

- Place the O-ring on a level, flat, and clean surface

- Determine the CS by measuring the thickness of the O-ring

- Determine the ID by measuring from one inner edge to the other inner edge

- Determine the OD by measuring from one outer corner to the other outer corner

Tolerances

One important consideration you need to keep in mind when sizing an O-ring is tolerance. Due to manufacturing limitations, there will always be some variance in the O-ring’s dimensions. For example, an O-ring size of 0.103 with a tolerance of ± 0.003’, the cross-section can measure between 0.100” and 0.106”. It is best to consult the manufacturer for their specific tolerance variance based on your selected O-ring material.

UC Components, Inc. RediVac® O-rings are designed for clean-critical applications

Our standard RediVac® O-rings are available in a wide range of standard AS568A inch-measure sizes and are manufactured from top-quality fluoroelastomer materials. Buna, silicone, and other materials are available, and specific chemistries may also be available upon request.

Our O-rings are cleaned and packaged in a certified Class 100/ISO Class 5 Cleanroom, making them suitable for immediate use in most HV, UHV, or EUV applications. Vacuum-baked O-rings are available for reduced outgassing under vacuum.

UC Components, Inc. has been the world leader in high vacuum hardware since 1974. We specialize in O-rings and fasteners for High Vacuum, Ultra High Vacuum, and other critical applications. View our parts catalog online to find the components you need, request a quote, or contact us for more assistance or additional information.