The Critical Art of Leak Detection in a Vacuum System

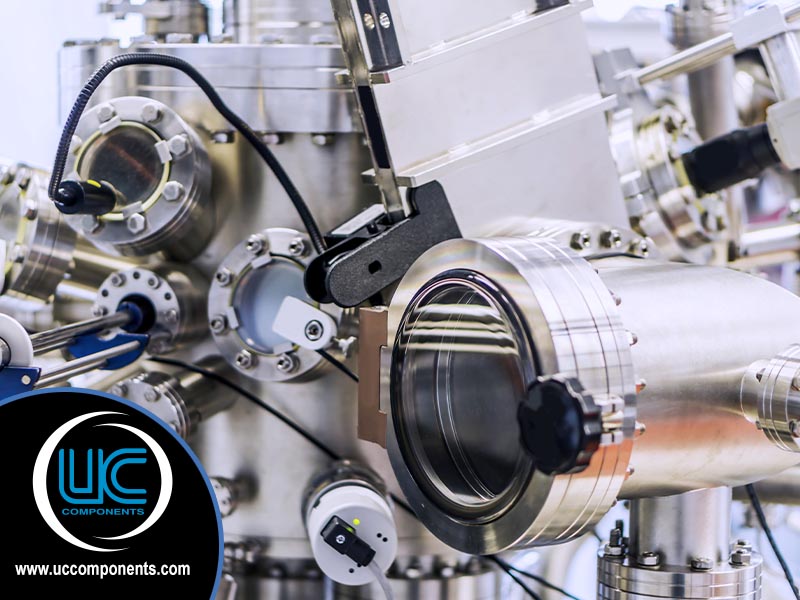

With the critical need to properly maintain and achieve a vacuum system, the “art” of leak detection is a skill that requires precise tools and

With the critical need to properly maintain and achieve a vacuum system, the “art” of leak detection is a skill that requires precise tools and

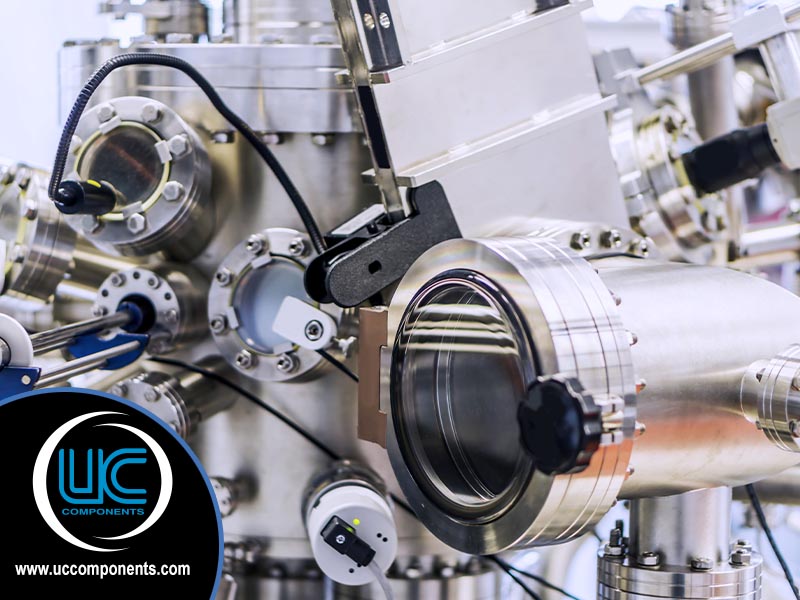

Permeation, or the permeability coefficient, of a polymer refers to the volumetric flow of gasses, under controlled conditions, through the material’s surface. Permeability does not

O-ring technology has come a long way since it was first developed in the late 1800s. Selecting the proper O-ring design and material is essential

Determining the exact size of an O-ring is one of the more challenging parts of ordering O-rings for your application. As you know, O-rings are

Fluoroelastomer, FKM, FPM, and Viton® are all different names for the same synthetic rubber material family. There are even more names for this material than

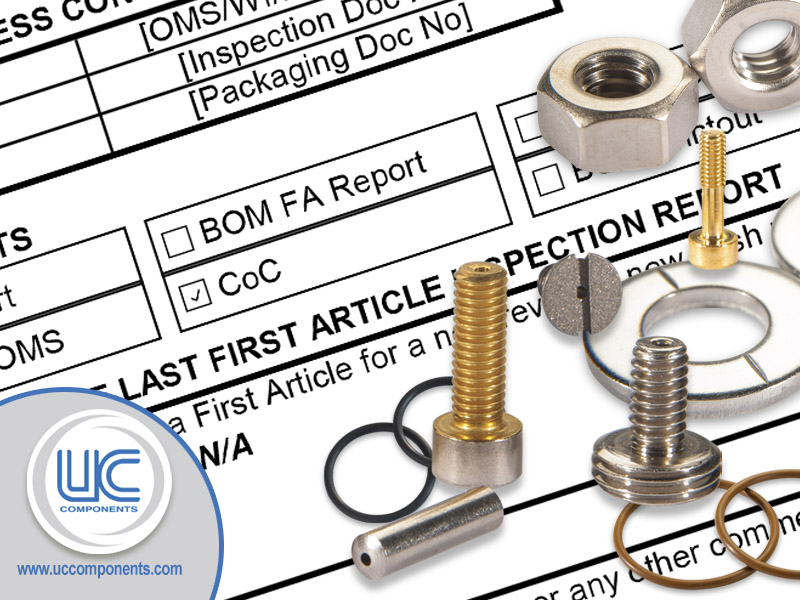

A flawed fastener or O-ring could ruin the effectiveness of your product, compromise your entire project or cause a variety of serious issues that can

O-rings are used in just about every industry and typically to block the flow of liquids, gasses, or other materials. Their actual makeup and function

There are a variety of O-rings on the market today which vary widely from manufacturer to manufacturer, the source of the materials used, and even

A First Article Inspection (FAI) is an official design verification and history method providing a detailed reporting of measurements for all key features of a

Anything that exists within the vacuum system that hurts or inhibits its proper function is considered a contaminant and must be addressed. Cleanliness is incredibly