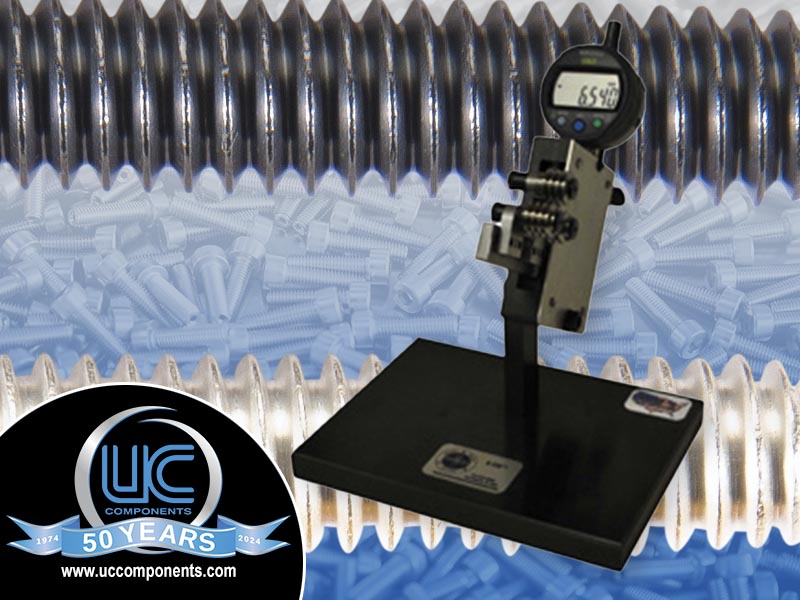

UC Components, Inc. proudly announces the acquisition and implementation of the state-of-the-art X-120 Adjustable Tri-Roll Thread Gage. This innovative addition to their arsenal of precision tools reinforces their commitment to delivering unparalleled quality and accuracy in fastener measurement.

Designed to meet the demanding needs of modern clean-critical manufacturing, the X-120 Adjustable Tri-Roll Thread Gage offers unparalleled versatility and accuracy. This cutting-edge machine employs advanced technology to precisely measure the intricate details of various fastener threads, ensuring adherence to the most stringent industry standards.

Key features of the X-120 Adjustable Tri-Roll Thread Gage include:

- Adjustable Functionality: The X-120 allows for effortless adjustment, catering to a wide range of fastener sizes and thread types with unparalleled ease and accuracy.

- Tri-Roll Design: Its unique tri-roll configuration ensures reliable and consistent measurement results, eliminating inaccuracies and streamlining the inspection process.

- Enhanced Efficiency: With rapid measurement capabilities, the X-120 significantly reduces inspection times, optimizing productivity and minimizing downtime.

- Robust Construction: Crafted from premium materials, the X-120 is built to withstand the rigors of industrial environments, guaranteeing long-term reliability and performance.

“We are thrilled to introduce the X-120 Adjustable Tri-Roll Thread Gage to our manufacturing process,” said Rick Anderson, President of UC Components, Inc. “This cutting-edge addition reflects our unwavering commitment to excellence and reinforces our ability to meet and exceed the evolving needs of our customers.”

By investing in the X-120 Adjustable Tri-Roll Thread Gage, UC Components, Inc. continues to uphold its reputation as an industry leader, delivering superior quality, precision, and reliability in every facet of our operations.

For more information about how the X-120 Adjustable Tri-Roll Thread Gage improves the fasteners offered by UC Components, or any other questions pertaining to their comprehensive range of precision fastener and seal solutions, please visit www.uccomponents.com or contact your UC Components, Inc. sales representative.

About UC Components, Inc.

UC Components, Inc. is a pioneer and innovator in vented screw manufacturing and has been the world leader in high vacuum hardware since 1974. Today, UC is one of the leading manufacturers of fastener and seal products for clean-critical environments of the 21st century, with a focus on plated, coated, polished, cleaned, and vented screws for High and Ultra High Vacuum equipment.

UC’s vented fasteners promote faster, more efficient pump-down of vacuum systems by providing a path through which trapped volumes of air can be evacuated from the vacuum chamber.

The UC Components, Inc. family of RediVac® products includes both inch and metric sizes of center and slot-vented screws, washers, and nuts. The RediVac® family also includes their cleaned and vacuum-baked O-rings, manufactured from top-quality fluoroelastomer materials and available in a wide range of standard AS568A inch-measure sizes. They also offer non-vented screws, nuts, and washers for through-holes in HV and UHV systems and other applications.

RediVac® means ready for vacuum service, now. The UC Components, Inc. RediVac® system ensures that every fastener and seal you order from them arrives ready to install immediately. This proprietary process reduces surface particulates and other contamination by utilizing a multi-stage cleaning, inspecting, and packaging process all done inside of our top-of-the-line certified Class 100/ISO Class 5 Cleanroom.

More information about the company, their services, capabilities, and the products they offer can be found on their website at www.uccomponents.com.