There are wide varieties of fastener hardware on the market today used by manufacturers in the assembly of every single product we use daily. Shoulder screws, while not typically found in your local hardware store, are extensively used in almost every industry because they are incredibly versatile and offer unique attributes when installed.

What are shoulder screws?

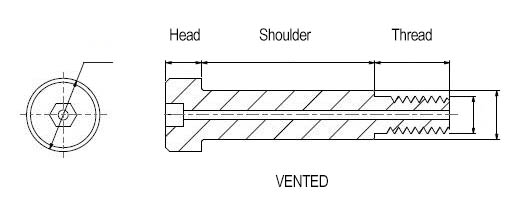

Shoulder screws, also called Shoulder Bolts or Stripper Bolts, are a type of screw with three distinct sections: the head, the unthreaded shoulder, and the threads. These types of screws consist of integral threads that are present on half or less of the screw shank and the rest of the shaft is enlarged and smooth to allow the bolted material the ability to rotate or move around the screw axis. These types of screws come in two varieties – commercial and precision. What is the difference between commercial and precision?

Commercial shoulder screws are all made to the ASME B18.3 standard (for inch sizes) and ASME B18.3.3 (for metric sizes). The shoulder diameter can measure between ¼” to 2”, the thread class is 3A, and the shoulder tolerance is +0.005/-0.005.

Precision shoulder screws, also known as tight tolerance shoulder screws, are not governed by standard sizing like commercial shoulder screws are. The shoulder diameter can measure between 3/32” to ½”, the thread class is 2A, and the shoulder tolerance can range between +0.000/-0.001 to -0.0005 to -0.0015. The shoulder length of a precision shoulder screw also has a tighter tolerance at -0.000 to +0.002.

What are shoulder screws used for?

Much like all other screws, shoulder screws are meant to hold objects together and in a particular position. However, these screws are designed for use in parts which requires a mounting pin, joint, shaft, dowel, pivot, or sliding motion.

Items such as:

- Bearings

- Bushings

- Machinery support

- Motion guiding

- Precision spacing

These types of screws are commonly used in mechanical applications such as:

- Engines

- Linkages

- Pulleys

- Vacuum systems

How do I select the right shoulder screw for my application?

To choose the correct shoulder screw for your application you will need to know the specifications needed for the head, shoulder, threads, and the material the screws will need to be made from. Shoulder screws are generally specified by their shoulder diameter and then by the shoulder length. The overall length of the shoulder screw includes the head height as well.

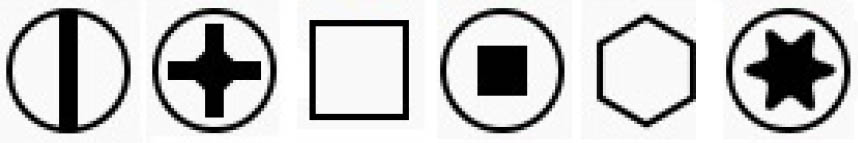

Screw Head

The screw head drive can be slotted, Phillips, square, Robertson, hex, or a variety of specialty hex shapes. The diameter of the head is typically twice the head height, and 30-50% larger than the shoulder diameter, with a flat top. They also generally have an undercut between the shoulder and the bottom of the head to allow components to mount flush against the head when installed.

Screw Threads

The threads of the shoulder screw must not exceed the shoulder diameter. The threads are typically relatively short but can be manufactured to any required length. The thread neck, which is the space between the shoulder and the threads, is typically undercut to allow it to seat flush with the threaded component. This is also the weakest point in the screw and over-torqueing can cause the screw to break or fracture at this point.

Screw Materials

Shoulder screws can be made from a variety of materials but they are almost always made out of a type of steel. The most common materials include:

- 303 Stainless Steel

- 316 Stainless Steel

- 17-4 PH Stainless Steel

- 416 Stainless Steel

- Alloy Steel

- Mild Steel

- Brass

- Plastic

Clean-Critical Shoulder Screws

UC Components, Inc. manufactures precision vented shoulder screws for High Vacuum, Ultra High Vacuum, and other clean-critical applications. These vented fasteners promote faster, more efficient pump-down of vacuum systems by providing a path through which trapped volumes of air can be evacuated from the vacuum chamber.

As a manufacturer of precision-grade shoulder screws we give engineers more flexibility to choose the head type, shoulder length, thread length, and any other variable that would best fit their application. We stock 303 shoulder screws but offer a full range of other material options that you can choose from. Our vented shoulder screws are available in a wide range of Inch-measure sizes and lengths. Metric screw sizes are also available. We also offer a variety of finish options to suit any need.

Request a quote or contact UC Components, Inc. for more information and to place your order.