Navigating the Skies: A flawed fastener can make or break your mission

A recent article about NASA opening a canister containing material scraped from the “potentially hazardous” asteroid Bennu caught our eye. As stated in the article,

A recent article about NASA opening a canister containing material scraped from the “potentially hazardous” asteroid Bennu caught our eye. As stated in the article,

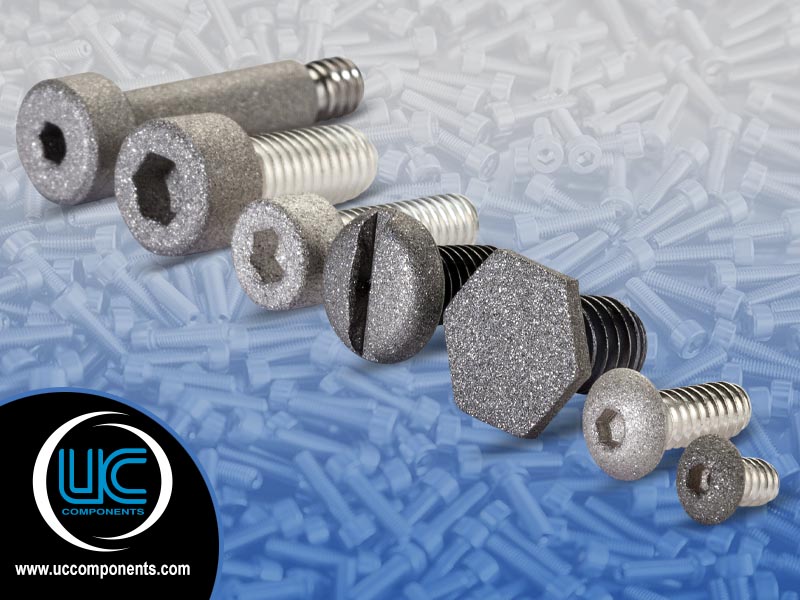

UC Components, Inc. takes pride in offering a comprehensive range of parts and finishes for various clean-critical industries. Our commitment extends beyond what you can

Fastener manufacturing is a multi-step process that includes (in a nutshell) material selection, forming, threading, heat treatment, surface treatment, inspection, testing, and finally, packaging and

UC Components, Inc. takes pride in offering a comprehensive range of parts and finishes for various clean-critical industries. Our commitment extends beyond what you can

Stainless steel is an extremely attractive material for a variety of industries and applications because the material offers several key advantages over other materials. Advantages

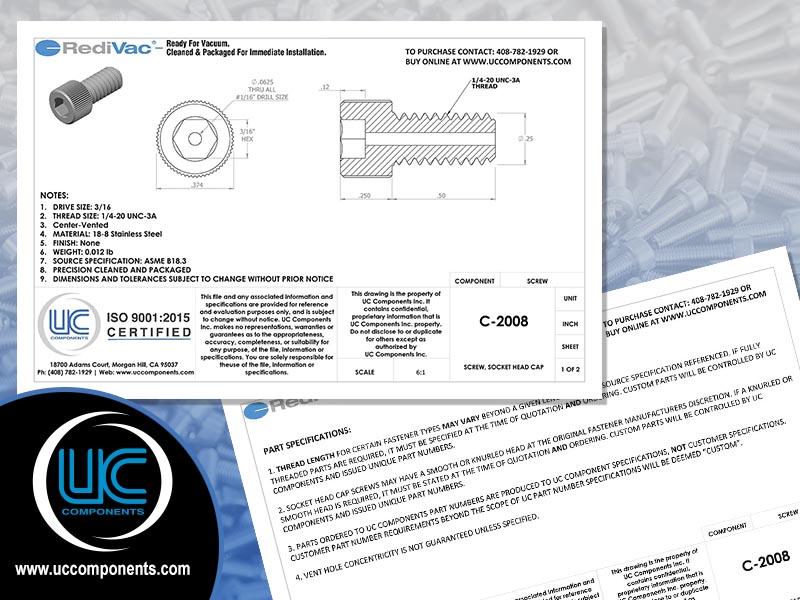

Fasteners are essential elements used to join parts in various industries, and a correct print, also known as a technical drawing or engineering drawing, is

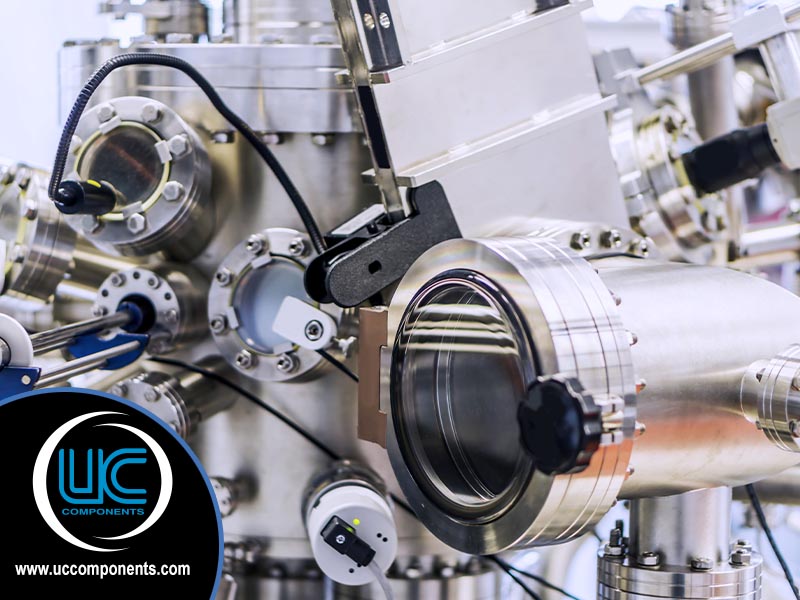

With the critical need to properly maintain and achieve a vacuum system, the “art” of leak detection is a skill that requires precise tools and

Titanium fasteners have become extensively used across many industries over the last few years. The material is very active, flexible/high plasticity, and offers a fantastic

A flawed fastener or O-ring could ruin the effectiveness of your product, compromise your entire project or cause a variety of serious issues that can

Platings affect not only how a metal fastener looks, but also its hardness, electrical conductivity, coefficient of friction, and how it will withstand corrosion or