Fastener manufacturing is a multi-step process that includes (in a nutshell) material selection, forming, threading, heat treatment, surface treatment, inspection, testing, and finally, packaging and shipping. When it comes to the threads, they are typically created through one of two processes – either rolled or cut. What is the difference, and how does the way the threads are created affect your application?

What are rolled fastener threads?

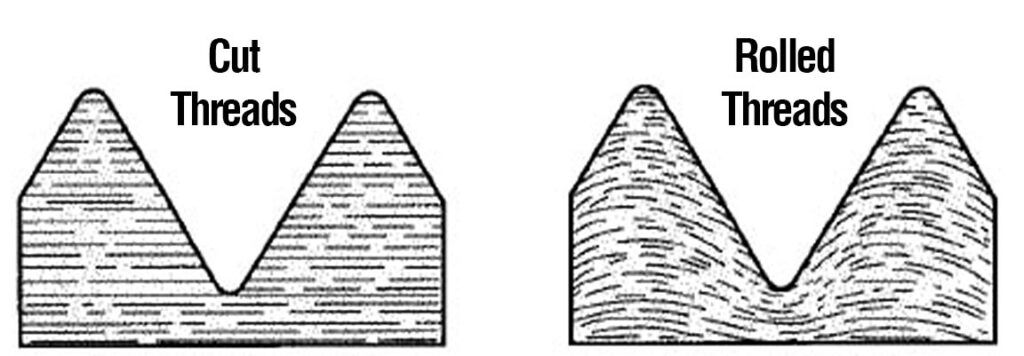

Rolled fastener threads are created through a process that involves deforming the material of the fastener, typically metal, by rolling it between two dies that have the negative profile of the desired thread shape.

The benefits of rolled fastener threads over other methods, such as cut or ground threads, include increased strength and resistance to fatigue and improved thread profile and dimensional accuracy. This is because the rolling process produces a compressive force on the material, strengthening the thread and removing any surface imperfections that could lead to stress concentrations or crack initiation.

Rolled fastener threads are commonly used in applications requiring high strength and reliability, such as the aerospace, automotive, and construction industries. They can be found in various fasteners, including bolts, screws, studs, and threaded rods.

What are cut fastener threads?

Cut fastener threads are created by removing material from the fastener to create the thread shape, typically using a cutting tool such as a tap or a die.

The benefits of cut fastener threads include flexibility and ease of manufacturing, and the ability to produce a wide range of thread sizes and shapes. Cut threads are also relatively easy to repair or modify if necessary.

However, cut threads can have some drawbacks when compared to rolled threads. They may have lower strength and fatigue resistance due to the removal of material, and the thread profile and dimensional accuracy may not be as precise as with rolled threads. Additionally, cut threads can create burrs or other surface imperfections that could lead to stress concentrations or other catastrophic issues.

Cut fastener threads are widely used in many industries, including automotive, construction, and general manufacturing, especially for smaller fasteners or applications where high strength is not as critical.

So, which one is a better choice for your application?

Determining whether rolled or cut fastener threads are better for your application depends on your specific application’s requirements and considerations, such as strength, durability, precision, and cost-effectiveness.

Rolled threads are generally stronger and more resistant to fatigue due to the compressive force generated during the rolling process. They also tend to have a more precise thread profile and dimensional accuracy, which can improve the overall performance of the fastener. Rolled threads are commonly used in critical applications requiring high strength and reliability.

Cut threads, on the other hand, are more flexible in terms of the range of thread sizes and shapes that can be produced. They are also easier to manufacture and can be repaired or modified if necessary. Cut threads are commonly used in applications where high strength is not as critical, such as in general manufacturing, construction, and automotive industries.

How can fasteners from UC Components, Inc. help you?

UC Components, Inc. has been the world leader in high vacuum hardware since 1974. We offer a variety of fasteners, including, but not limited to, standard and vented screws, washers, and hex nuts. We offer numerous finish options, specialized venting designs, complete custom product development, and Class 100/ISO Class 5 Cleanroom cleaning & packaging. View our parts catalog online to find the components you need, request a quote, or contact us for more assistance or additional information. If you do not see the fastener, material, or O-ring that you need listed in our standard products, please give us a call! We may not stock it, but we are happy to acquire or manufacture just about any fastener or O-ring you need.