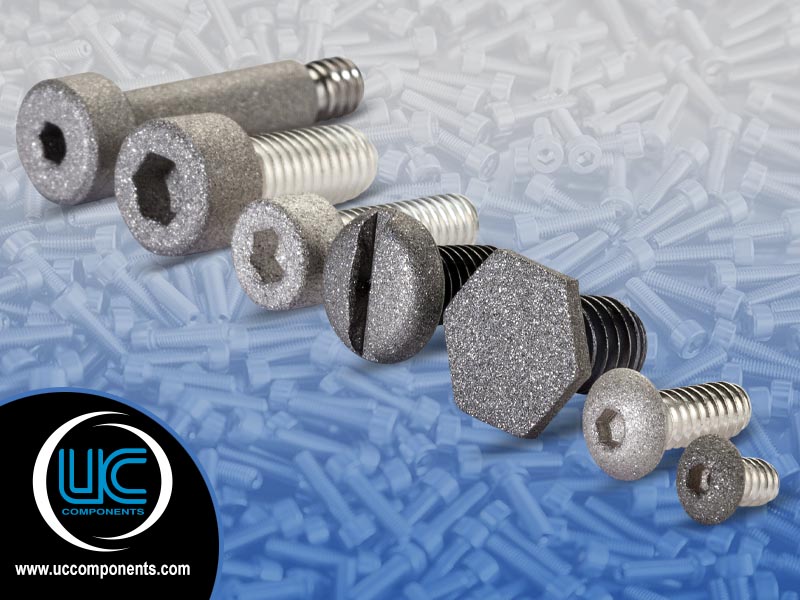

UC Components, Inc. takes pride in offering a comprehensive range of parts and finishes for various clean-critical industries. Our commitment extends beyond what you can find in our extensive standard listings in our online catalog. We also offer a wide range of prototyping, custom parts, custom services, and finishes that aren’t in the catalog, such as grit blasting.

Grit-blasting is a surface preparation technique that propels abrasive particles against a fastener’s surface at high speeds to create a roughened texture. Grit-blasted parts are often used for shielding in deposition systems where thin films or coatings are applied to a substrate. Why? Several reasons, including but not limited to:

1.) Improved Adhesion: The roughened surface created by grit-blasting provides a better substrate for adhesion. When a thin film is deposited onto a smooth surface, adhesion may not occur, or it may adhere poorly, and the film could delaminate or peel off over time. The increased surface area and roughness created by grit-blasting enhances the adhesion of the deposited material, leading to a more durable and reliable coating.

2.) Reduced Contamination: Grit-blasting can help remove contaminants, oxides, or other impurities from the surface of the fastener being coated. This is crucial in deposition processes, as contaminants can negatively impact the quality and properties of the deposited films. The surface is cleaned and prepared for deposition by grit-blasting the parts, reducing the likelihood of defects in the coating.

3.) Uniform Deposition: The roughened surface from grit-blasting can promote a more uniform and consistent deposition of the coating material. In some cases, a smooth surface may lead to uneven deposition, causing variations in thickness and properties across the coated surface. The textured surface grit-blasting creates can help distribute the deposited material more evenly.

4.) Enhanced Mechanical Bonding: Grit-blasting increases the surface area and creates a microscopically rough surface profile. This roughness allows for better mechanical interlocking between the substrate and the deposited material, enhancing the overall bonding strength.

5.) Surface Activation: Grit-blasting can activate the material’s surface by creating micro-indentations and introducing stress. This activation can improve the surface’s wettability by the deposited material, facilitating better coverage and adhesion during deposition.

Learn more about fastener finishing & our standard options here> https://www.uccomponents.com/venting-finishing/finishing/

Looking for something else? Contact us to explore extensive offerings tailored to meet your specific needs and requirements.