With the critical need to properly maintain and achieve a vacuum system, the “art” of leak detection is a skill that requires precise tools and training. It is considered an “art” due to the complexity, experience required, and variations of vacuum systems currently manufactured. You need:

- A high level of knowledge regarding materials and chemical interactions under a vacuum.

- Adequate gauging and instrumentation for evaluation of the vacuum level.

- Leak detection equipment and tools.

- A good working knowledge of the specific system operation, process, and internal architecture.

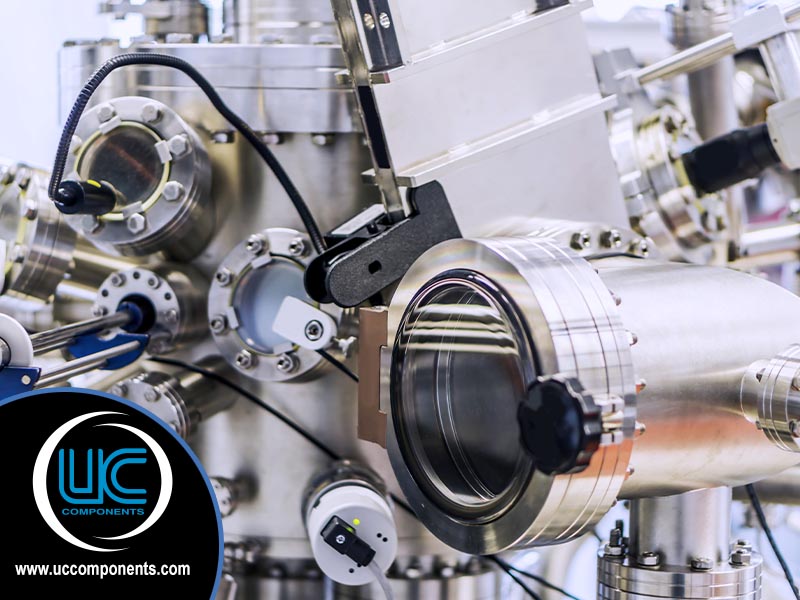

Materials used in a vacuum system are very specific since they will be exposed to extreme conditions. Those include (but are not limited to):

- Outgassing: all materials, components, and surfaces in a vacuum outgas. This can be the material itself, a component of the material, or contamination on or within the material. Ensuring all fasteners are properly vented and precision cleaned will help prevent virtual leaks and ensure a proper vacuum level.

- Chemicals and Gases: many vacuum deposition systems utilize various gases for venting or processing. Chemicals are used for surface preparations and cleaning. They can leave behind unwanted contaminates and cause unwanted reactions with vacuum processes and coated devices.

- High Energy Particles: these particles can come from heat, plasmas, emissions, or other active devices in the system.

- And more.

Detecting leaks in a sealed vacuum system can be challenging, but several methods can be used to identify leaks. Here are the five most common ways leaks can be detected in a vacuum system (though certainly not every way):

- Gas Leak Detection: The most commonly used gas to test for leaks is helium via a sniffer or connected directly to the system’s plumbing. Helium leak detection is a sensitive and accurate method of detecting leaks in vacuum systems. Helium is used as a tracer gas, and a mass spectrometer is used to detect any helium leaking from the system. This method is particularly useful for locating small leaks.

- Liquid-Based Detection: It is possible to use equipment gauging and a solvent, like alcohol, to address gross leaks. However, using liquid to detect leaks in a vacuum system is not recommended, as liquids can damage the system and interfere with its operation. Additionally, introducing liquids into a vacuum system can cause contamination, affecting future system performance.

- RGA (Residual Gas Analyzer) Leak Detection: This unit resides inside the vacuum system and allows the engineer to view and monitor the specific peaks relating to the partial pressure of individual atomic peaks and trends. This method is preferred since it provides a specific atomic peak for detection. RGA leak detection is also the most expensive and requires extensive training.

- Ultrasonic Detection: Ultrasonic leak detectors work by detecting the high-frequency sound waves that are produced when a gas or fluid leaks through a small orifice or crack. Basically, you would scan the vacuum system with the ultrasonic detector, listening for the specific sound of a leak through connected headphones or speakers. If a leak is detected, the detector typically emits a beep or other audible signal to alert the operator. This method is not as accurate for very small leaks.

- Visual Inspection: Inspect all the components of the vacuum system for any signs of damage or wear, such as cracks, breaks, or corrosion. Check all the seals, gaskets, and fittings for any signs of wear or damage. This method is limited to finding leaks large enough to be visible to the naked eye.

Typically, a leak is discovered after a specific event or routine maintenance activity has been performed. Keep in mind that something as minute as a wayward fingerprint or single eyelash can effectively simulate or create a minor vacuum leak, depending on your system’s vacuum level requirements. Several signs may indicate the system has a leak, such as:

- Reduced overall performance of the system.

- Unexpected rise in the vacuum level.

- Unusual sounds (such as whistling or hissing).

- Unusual odors (such as oil or solvent).

- Any visual cracks, breaks, or corrosion.

- And more.

What can you do if you suspect a leak?

If you suspect you have a leak, first look at when the last maintenance cycle was performed on the system and check any notes from that maintenance. What parts were replaced, if any? Also, be sure that the instrumentation displays the proper values. If you suspect a leak in your vacuum system, addressing the issue as soon as possible is essential. A leak can cause damage to the system and affect its performance, and it can also be a safety hazard. It is recommended to consult with a trained technician or engineer who can help identify and repair the leak and provide guidance on proper maintenance and care of the vacuum system.

Looking for more?

Watch this quick YouTUBE video “Air-tight vs. Vacuum-tight”:

What can you do to minimize the possibility of a leak?

Proper fasteners and seals are needed to operate and maintain critical processes in a vacuum environment.

- For fasteners, we recommend vented screws and washers made from proper vacuum-compatible materials. These fasteners must also be properly cleaned, handled, and installed. Simply rinsing them with a solvent will not ensure cleanliness.

- For elastomeric seals, vacuum-baked O-rings will ensure the material has already outgassed the water vapor or easily diffused impurities. Vacuum baking does not affect the durometer or sizing of the elastomer. O-rings also need to be properly cleaned, handled, and installed.

How can fasteners and O-rings from UC Components, Inc. help you?

UC Components, Inc. has been the world leader in high vacuum hardware since 1974.

Our standard RediVac® O-rings are available in a wide range of standard AS568A inch-measure sizes and are manufactured from top-quality fluoroelastomer materials. Buna, silicone, and other materials are available, and specific chemistries may also be available upon request.

We offer a variety of fasteners, including, but not limited to, standard and vented screws, washers, and hex nuts. We offer numerous finish options, specialized venting designs, complete custom product development, and Class 100/ISO Class 5 Cleanroom cleaning & packaging.

View our parts catalog online to find the components you need, request a quote, or contact us for more assistance or additional information. If you do not see the fastener, material, or O-ring that you need listed in our standard products, please give us a call! We may not stock it, but we are happy to acquire or manufacture just about any fastener or O-ring you need.