Outgassing is often an underestimated concern in vacuum systems, cleanrooms, and high-performance assemblies, especially when using fasteners and sealing materials not engineered explicitly for such environments. Outgassing is the release of trapped or absorbed gases from materials when exposed to a vacuum or elevated temperatures. These gases can lead to contamination, pressure instability, and even system failure in sensitive applications such as aerospace instrumentation, semiconductor manufacturing, and optical systems.

One of the primary sources of outgassing in mechanical assemblies is trapped gas in blind-tapped holes and between mated surfaces, which occurs when traditional fasteners are used without venting provisions. Standard screws can create hermetic pockets where air and volatile residues become trapped during assembly. These “virtual leaks” or trapped gases are slowly released in a vacuum, contributing to prolonged pump-down times and volatile contamination on critical surfaces.

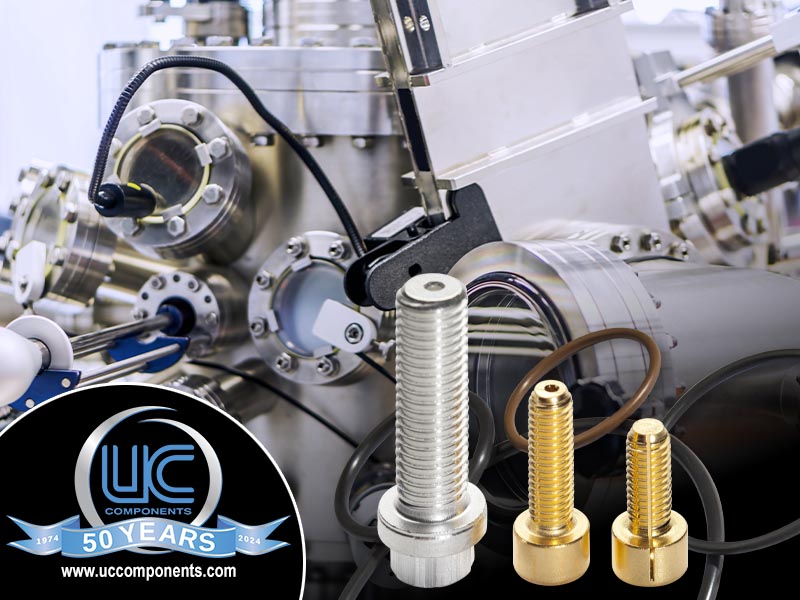

Vented fasteners, often designed with a center-bore or axial groove, allow these gases to escape more quickly, reducing the time to achieve low pressures and mitigating contamination risk. However, engineers must account for proper torque retention and structural integrity, as vented fasteners may exhibit slightly different mechanical properties due to geometry changes.

Elastomeric O-rings are standard in vacuum seals and high-integrity enclosures, but their polymeric nature makes them prime outgassing culprits. Even so-called “vacuum-compatible” O-rings (like those made from Viton, Kalrez, or silicone) can release plasticizers, processing agents, or absorbed water vapor under vacuum or heat. More critically, some compounds allow permeation, where external gases slowly diffuse through the elastomer, leading to gradual contamination or pressure shifts.

Compounding this issue is the compression set of O-rings over time. As the elastomer deforms and loses elasticity, it can introduce microleaks or gas channels. This is especially problematic in dynamic applications or thermal cycles with mission-critical seal integrity.

Engineers should carefully evaluate the fasteners’ and seals’ material composition, thermal stability, and processing history to minimize these issues. Using pre-baked components, vacuum-rated lubricants, and vented fasteners can dramatically reduce residual gas load. Additionally, selecting O-ring compounds certified for low outgassing (per ASTM E595 or ECSS-Q-ST-70-02C) is vital in aerospace or optical systems.

How do vacuum-baked fasteners and O-rings help to mitigate outgassing issues?

Vacuum-baked fasteners and O-rings undergo a specialized high-temperature treatment process in a vacuum environment designed to reduce outgassing significantly. The vacuum bake-out process drives off moisture, hydrocarbons, and other surface or absorbed contaminants, ensuring that the metal fasteners and/or O-rings are cleaned to the highest standards. The result is components with much lower outgassing rates, which is ideal for sensitive environments where precision and purity are paramount.

Ultimately, even the smallest mechanical choices, like using a vented screw or switching to a fluoropolymer O-ring, can significantly influence the cleanliness and performance of a complex system.

Why choose vented fasteners and O-rings from UC Components?

UC’s fasteners have been instrumental in vacuum and other clean-critical applications since 1974. We offer a wide variety of fasteners and O-rings, including, but not limited to, standard and vented screws, washers, and hex nuts in multiple materials. We offer numerous finish options, specialized venting designs, complete custom product development, and Class 100/ISO Class 5 Cleanroom cleaning & packaging.

View our parts catalog online to find the components you need, request a quote, or contact us for more assistance or additional information. If you do not see the fastener, material, or O-ring that you need listed in our standard products, please give us a call! We may not stock it, but we are happy to acquire or manufacture just about any fastener or O-ring you need. A live Certified Fastener Specialist is waiting to hear from you and will help you find the perfect part and finish. From student to scientist, no UC customer is ever too small – and no job is too big! Contact UC Components today.