Can you afford a poor fastener or O-ring choice?

A flawed fastener or O-ring could ruin the effectiveness of your product, compromise your entire project or cause a variety of serious issues that can

A flawed fastener or O-ring could ruin the effectiveness of your product, compromise your entire project or cause a variety of serious issues that can

Platings affect not only how a metal fastener looks, but also its hardness, electrical conductivity, coefficient of friction, and how it will withstand corrosion or

Did you know that the first known recorded use of screws occurred during the time of the ancient Greeks; they used them in devices to

Over 200 billion fasteners are created every year in the United States alone. Though not all fasteners are created equal. Choosing the right fastener material

Fasteners installed in any piece of equipment need to be long-lasting and able to withstand repeated use (when appropriate). Coatings and platings are designed for

Fasteners play a crucial role in many industries, including aerospace. They are prominent in the manufacture and assembly of all aircraft and spacecraft; both in

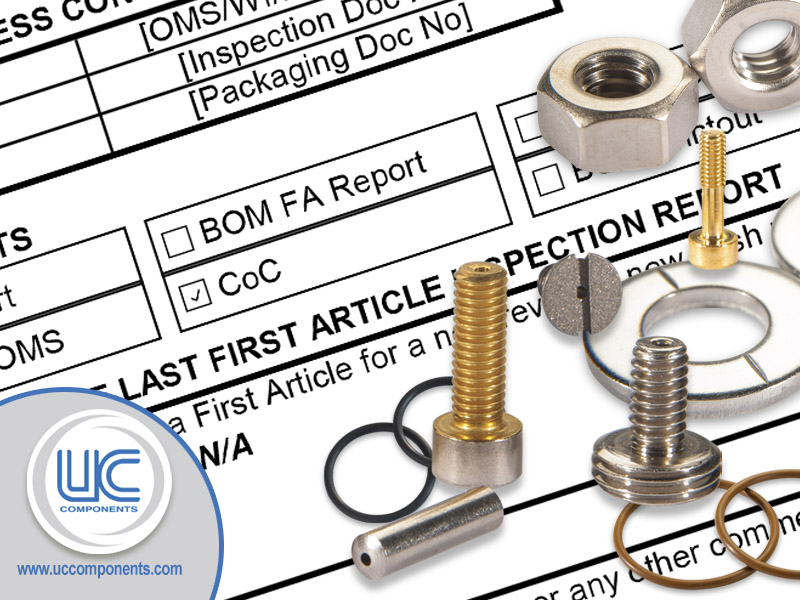

A First Article Inspection (FAI) is an official design verification and history method providing a detailed reporting of measurements for all key features of a

Vacuum chambers must remain clean and free of contaminants and volatile materials that would lead to contamination of the entire system. Assembly for critical applications

A virtual leak is a trapped volume of gas within a vacuum chamber that cannot be easily pumped out due to restrictions in the path

High-temperature fasteners are used extensively in critical industries such as semiconductor, aerospace, automotive, and oil/gas. They are specially designed to be able to withstand high