Stainless steel is an extremely attractive material for a variety of industries and applications because the material offers several key advantages over other materials. Advantages such as:

- Corrosion resistance: It is highly resistant to corrosion and rust since it contains a minimum of 10.5% chromium, which forms a protective oxide layer on its surface. This makes it ideal for fasteners used in outdoor or corrosive environments.

- Durability: It is a strong and durable material that can withstand high levels of stress, pressure, and mechanical forces. It maintains its strength and integrity even in extreme temperatures.

- Aesthetic appeal: The material has an attractive polished appearance that retains its luster over time.

- Hygiene and cleanliness: It is non-porous and resistant to bacteria, making it suitable for fasteners used in industries with strict hygiene requirements, such as food processing, healthcare, and pharmaceuticals. It can be easily cleaned and sanitized, reducing the risk of contamination.

- Compatibility: Stainless steel fasteners are compatible with a wide range of materials, including other metals, plastics, and composites. This versatility allows for their use in various applications, from construction and automotive to electronics and marine industries.

- Longevity: It offers excellent longevity with minimal maintenance.

- Recyclability: It is highly recyclable and can be repurposed without losing its essential properties, reducing waste and conserving resources, which makes it an environmentally friendly choice.

What are BUMAX Stainless Steel Bolts, and what makes them unique?

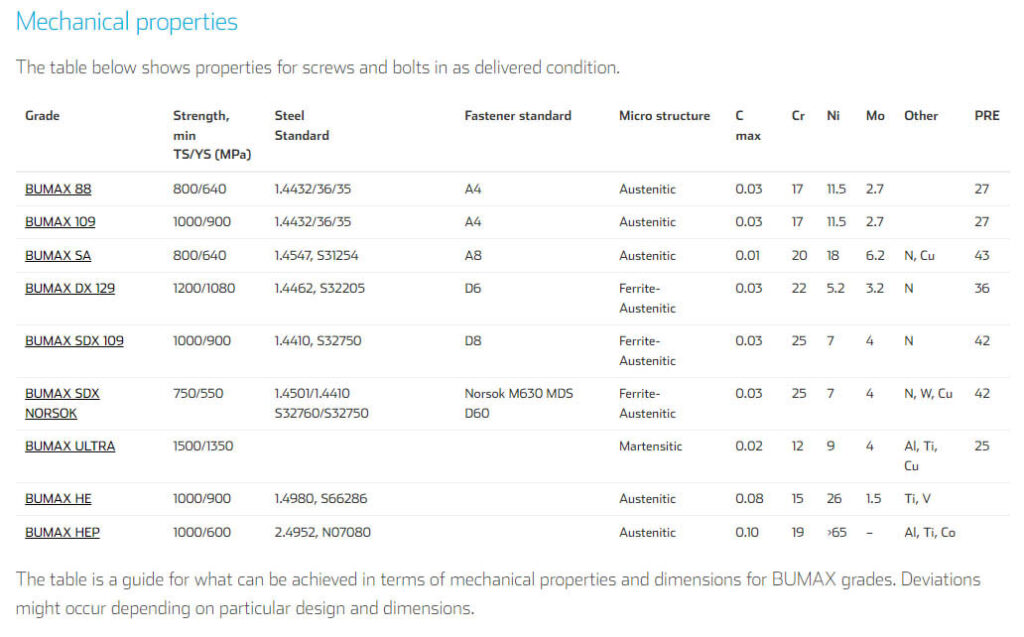

BUMAX® manufactures unique stainless steel fasteners in various steel grades, providing optimal safety and reliability for the most demanding applications. These unique bolts offer magnetic permeability, corrosion resistance, mechanical strength, good ductility, extreme temperature resistance, superior fatigue resistance, and more.

The superiority of BUMAX® is unmatched for stainless steel bolts. For example, BUMAX® DX 129 is currently the only stainless steel bolt in the world that is comparable to 12.9 carbon steel in strength.

Magnetic Permeability

Relative magnetic permeability refers to a material’s ability to attract and conduct magnetic lines of flux. The more conductive material is to magnetic fields, the higher its permeability. Austenitic BUMAX fasteners with very low magnetic permeability can be made for advanced applications such as nuclear fusion reactors or particle accelerators. They can also be made with very high magnetic permeability, low coercive field strength, and high saturation magnetization.

| Grade of BUMAX fastener | Relative magnetic permeability at 68ºF (20ºC) |

| BUMAX 88 | 1.006 |

| BUMAX 109 | 1.007 |

| BUMAX Nitro | 1.003 |

| BUMAX SA | 1.003 |

| BUMAX LDX | 100 |

| BUMAX DX | 100 |

| BUMAX SDX | 100 |

| BUMAX HDX | 100 |

| BUMAX Ultra | 1000 |

| BUMAX HE | 1.007 |

| BUMAX HEP | 1.001 |

Corrosion Resistance

The protective chromium oxide layer on the surface of stainless steel gives the material its corrosion resistance properties. However, that layer may be affected by the fastener’s design, surface quality, stresses, and more. If the chromium oxide layer cannot be maintained, possibly due to an overly aggressive environment, the metal will be exposed, and corrosion will occur.

The most common forms of corrosion include (but are not limited to):

- General corrosion, which is characterized by uniform corrosion over the surface.

- Pitting corrosion, which is typically localized to a small area and creates pits in the metal.

- Crevice corrosion, which typically occurs in concealed places such as small gaps and contact areas between parts.

- Galvanic corrosion, which is the corrosion of an alloy used in conjunction with another incompatible alloy in the same application.

- Stress corrosion, which can occur when a metal is exposed to tensile stresses in a corrosive environment, often at elevated temperatures above 140°F (60°C).

Mechanical Strength

BUMAX stainless steel fasteners range from strength class 8.8 to 16.9 for applications where downsizing, clamping force, and strength are critical. These fasteners offer a unique combination of strength and good ductility and are also resistant to hydrogen embrittlement.

Benefits of high-strength fasteners include (but are not limited to):

- Opportunities to downsize the fastener or reduce the number of fasteners with maintained clamp load.

- Weight savings.

- Compact design and smaller screw joints.

- Ability to withstand higher static or dynamic stresses.

- Greater safety.

- Higher resistance against relaxation.

Temperature Resistance

Temperature affects an alloy’s fracture toughness, strength, thermal expansion, ductility, corrosion resistance, fatigue resistance, and more. Depending on the particular grade, BUMAX fasteners can handle operating temperatures between -269°C and 1,472°F (800°C).

Fatigue Strength

Fatigue fracture often begins with a stress concentration in inclusions, slags, or surface defects. All BUMAX bolts are made with the best possible European steel and are strain-hardened and thread-rolled to enhance fatigue resistance.

What industries and applications benefit from BUMAX fasteners?

The essential properties of these specialty fasteners, such as corrosion resistance, temperature resistance, mechanical strength and magnetic permeability, make them the perfect choice for a wide variety of critical industries and applications.

Industries and applications including (but not limited to):

- Oil & Gas

- Marine

- Sub-Sea Operations

- Pulp & Paper

- General Engineering

- Pumps and pump systems

- Energy (Wind, Tidal, Nuclear)

- Pressure Equipment

- Defense Industry

- Exhaust Systems

- Turbo Chargers

- And more

How do you choose the correct fastener for your application?

- Evaluate the environment and the likelihood of accumulated deposits.

- Use a design that minimizes crevices and allows rain to wash away deposits.

- Use a stainless steel fastener with equivalent or higher corrosion resistance than the component being fastened.

- Avoid mixing materials with a significant difference in electrode potential.

- Still unsure or need guidance, ask a professional in the industry, such as the fastener engineers at UC Components, Inc.

How can fasteners from UC Components, Inc. help you?

UC Components, Inc. has been the world leader in high vacuum hardware since 1974. While suitable materials, coating, plating, or finishing treatment for your fastener application is best defined by your process engineer, we are always here to assist you.

We offer a variety of fasteners, including but not limited to standard and vented screws, washers, and hex nuts. We offer numerous finish options, specialized venting designs, complete custom product development, and Class 100/ISO Class 5 Cleanroom cleaning & packaging. View our parts catalog online to find the components you need, request a quote, or contact us for more assistance or additional information. If you do not see the fastener, material, or O-ring that you need listed in our standard products, please give us a call! We may not stock it, but we are happy to acquire or manufacture just about any fastener or O-ring you need.