The Advantages of Buying Pre-Cleaned and Packaged Fasteners & O-Rings

Manufacturing fasteners and O-rings is a dirty job. The machining process leaves behind metal shavings, dust, and debris. Lubricants and coolants used to reduce friction

Manufacturing fasteners and O-rings is a dirty job. The machining process leaves behind metal shavings, dust, and debris. Lubricants and coolants used to reduce friction

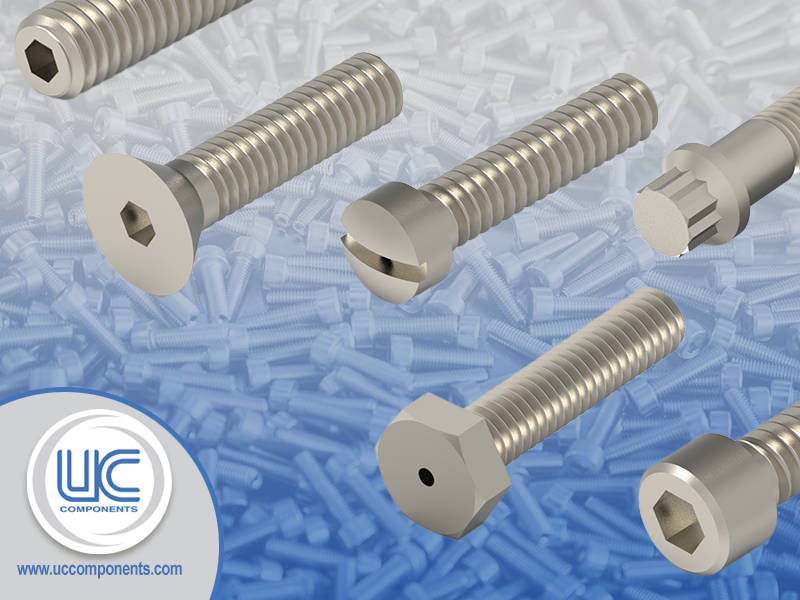

Fastener manufacturing is a multi-step process that includes (in a nutshell) material selection, forming, threading, heat treatment, surface treatment, inspection, testing, and finally, packaging and

Stainless steel is an extremely attractive material for a variety of industries and applications because the material offers several key advantages over other materials. Advantages

Did you know that the first known recorded use of screws occurred during the time of the ancient Greeks; they used them in devices to

Fasteners installed in any piece of equipment need to be long-lasting and able to withstand repeated use (when appropriate). Coatings and platings help prevent or

Over 200 billion fasteners are created every year in the United States alone. Though not all fasteners are created equal. Choosing the right fastener material

Fasteners installed in any piece of equipment need to be long-lasting and able to withstand repeated use (when appropriate). Coatings and platings are designed for

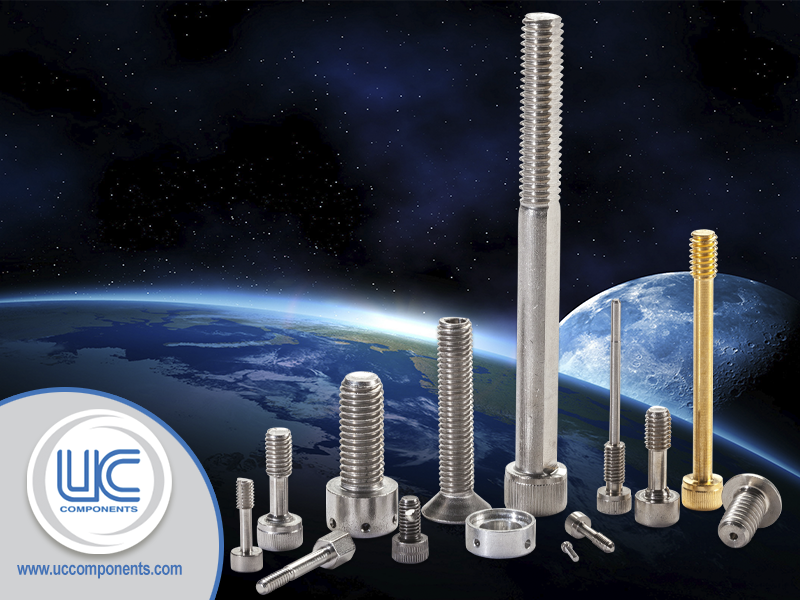

Fasteners play a crucial role in many industries, including aerospace. They are prominent in the manufacture and assembly of all aircraft and spacecraft; both in

UC Components, Inc. is proud to be a socially and environmentally responsible business partner. We work hard to continually update our products, materials, and machining

Galling is one the most common problems when tightening fasteners. Galled nuts and bolts may even pass all required inspections (mechanical, threads, material, etc.), yet